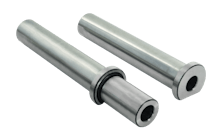

Hand-E Manufacturers in high-mix, low-volume environments can set up these Robotiq adaptive grippers in just 10 minutes. Designed for collaborative robots, they are ideal for assembly tasks, and appropriate for use in rugged environments. They are well-suited to production settings that involve minimal variation in object sizes.

What’s new? Robotiq’s Hand-E C10 model. Built for industrial applications and harsh environments, Robotiq’s concentric gripper for machine tending offers automatic part detection, position feedback and part validation. It has an ergonomic shape for hand-guiding.

Benefits Convenience, precision and reliability. The plug-and-play gripper is ideal for high-precision machining and assembly tasks.

Robotiq, Lévis, Quebec, 888-762-6847, www.robotiq.com

Vital Statistics

Hand-E |

Hand-E C10 |

|

|

Adjustable stroke |

About 2 inches |

About 1.6 inches |

|

Grip force per finger |

4.5 pounds force to 41 pounds force |

39.34 pounds force |

|

Maximum payload |

15 pounds |

22 pounds |

|

Gripper mass |

2 pounds |

3.3 pounds |

|

Number of cycles under warranty |

5 million |

|

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.