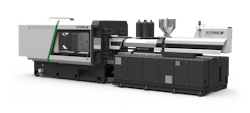

Injection molding machines (IMMs) Stork has offered IMMs in North America for about 20 years, with full service and sales support available in the U.S. over about the past year. The range includes four series: the Food-line, Crate-line, Pot-line and Pail-line. Overall clamping forces range from 200 tons to 2,000 tons.

What’s new? A specially designed high-speed Food-line 440-ton IMM, known as the 4400-3550, for turning recycled PET (rPET) into packaging. Shown at Fakuma, the IMM made 1-liter containers composed of half virgin PET and half rPET.

Benefits The ability to produce thin-walled rPET containers in high volumes. The machine at Fakuma had a cycle time of 6.2 seconds and produced 580 parts per hour. It had multiple features for handling rPET, including special software to compensate for differences in the melt-flow index of regrind material and a specially designed movable platen for extreme stiffness of the platen. It also had an injection pressure of about 43,500 pounds per square inch, a special plasticizing screw and check valve and extra-high-injection speed capabilities.

Stork IMM USA LLC, Swedesboro, N.J., 856-467-3399, www.storkimm.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.