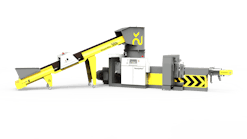

Roberto This welding system from C-Hawk Technology integrates sensor technologies, artificial intelligence-driven controls and collaborative robotic arms certified for use in clean rooms. It’s designed to make the plastics welding process more efficient for manufacturers of components, assemblies and subassemblies for the semiconductor and health-care industries. Among other features, it comes with a user-friendly interface and real-time monitoring and adjustments that allow it to adjust welding parameters on the fly.

What’s new? The welding system, introduced in November.

Benefits Quality, repeatability, precision, efficiency and scalability. With the technology, users can experience reductions in labor demands and production costs. According to its maker, compared with manual welding, the Roberto technology produces less waste and uses less energy, and is 25 percent faster and 30 percent more efficient in terms of output; it also cuts error rates in half.

C-Hawk Technology International Inc., Hayward, Calif., 510-962-8778, www.c-hawk.com

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.