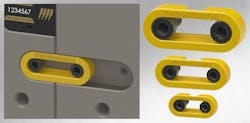

SeVG+ servo motor This compact Mold-Masters component has a direct drive and can precisely control the opening and closing, as well as movement speed, of an injection mold valve pin, making it appropriate for demanding applications, such as the production of large automotive parts.

What’s new? The motor, now in its second generation. Compared to its predecessor, the motor’s installed height has been reduced by 48 percent, down to 114mm. It is compatible with Mold-Masters' full range of valve pin diameters, from 2mm to 9.5mm, and incorporates integrated water-cooling channels for high-temperature applications. It is also compatible with molds utilizing magnetic clamps.

Benefits Simplified mold designs, enhanced performance and reliability, and minimized spare-part requirements. Because it is a direct-drive unit, the motor requires no levers, gear boxes or other components to move the valve pin. Its minimal height limits the thickness of mold plates needed to accommodate it; and its size is interchangeable with Mold-Masters' hydraulic actuator, giving mold makers flexibility in designing molds. Its design advantages result in faster response rates and more precise movements. In addition, rather than separate power and encoder cables, the motor has only a single cable connection that can swivel 180 degrees. This speeds assembly times. Lastly, the valve pin can be quickly and easily installed, or removed, without dismantling the motor from the hot-runner system.

Mold-Masters, Georgetown, Ontario, 905-877-0185, www.moldmasters.com