Epson Robots added a second model to its Flexion N series of six-axis robots, which features an arm that folds under itself to save space, and introduced a Synthis T SCARA robot.

The Flexion N6 joins the Flexion N2, which launched the product line in 2017. The Flexion N6 has a reach of 3.3 feet and can handle a payload up to 13.2 pounds.

The new robot has a motion range of plus or minus 180 degrees for the turning, lower and upper arm joints. The wrist mechanism can bend with a range of motion of plus or minus 125 degrees and can roll plus or minus 200 degrees. The wrist can also twist plus or minus 360 degrees on its axis. The Flexion N6 has a motion repeatability of plus or minus 0.04mm.

In comparison, the Flexion N2 has a reach of about 1.5 feet and a payload capacity of 5.5 pounds. Its wrist mechanism can roll with a range of motion of plus or minus 195 degrees and bend to plus or minus 130 degrees. The Flexion N2's motions are repeatable to plus or minus 0.02mm.

Both of the Flexion N-series robots use Epson's RC700A controller and RC+ 7.0 software. They also incorporate Epson's proprietary Residual Vibration Technology, which ensures high-speed operation and precise acceleration and deceleration. The arm design reduces space requirements by as much as 40 percent compared with a standard six-axis robot. Robots in the series are appropriate for vertical machine loading and unloading and use in tight spaces.

"Our N-series robots are ideal for a wide range of industries that require extreme precision and dexterity for handling small parts in a very tight environment," said Gregg Brunnick, director of product management.

The company also plans to offer a clean-room version of the Flexion N-series, featuring a reach of about 2.8 feet, as well as a standard version with the same reach.

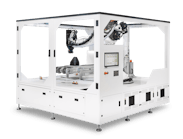

Epson also extended its Synthis T line of all-in-one SCARA robots with a larger model, the Synthis T6. The Synthis T series robots are primarily targeted at assembly applications but also are ideal for simple pick-and-place, part-handling and dispensing operations.

The Synthis T series features an all-in-one design that includes a built-in controller housed in the base of the robot and power for the end-of-arm tooling (EOAT), which eliminates the need for an external power source. The T6 runs on 110 volts or 220 volts and requires no encoder battery, which minimizes downtime for maintenance. The Synthis T series is designed to be easily installed in minutes, requiring less time for system integration compared with more expensive and complex linear-slide systems.

The Synthis T6 has a reach of up to about 2 feet and a payload capacity of 13.2 pounds. The positioning of Joints 1 and 2 is repeatable to plus or minus 0.04mm. The positioning of Joints 3 and 4 is repeatable to plus or minus 0.02mm and 0.02 degree, respectively. The robot has a cycle time of 0.49 second.

The Synthis T6 joins the Synthis T3, which has an arm length of 1.31 feet, a maximum payload of 6.6 pounds and achieves a positioning accuracy that is repeatable to plus or minus 0.02mm for Joints 1-3, and 0.02 degree for Joint 4. It attains a cycle time of 0.54 second.

Epson also has introduced a new force-control system for its SCARA, Cartesian and six-axis robots that enables the robots to tackle tasks that require high-precision motion guidance. Force Guide is a tightly integrated force-control system that allows Epson robots to sense and make precise moves using force feedback data.

The Force Guide control system is designed for easy configuration and setup, featuring a point-and-click interface with graphical wizards, charts and other set-up objects pre-configured to reduce the time needed to create an operation profile for operations such as part insertion, grinding or polishing.

Force Guide control is powered by Epson's proprietary Quartz Technology, which enables the robot to detect six axes of force. An internal sensor integrated with a real-time servo system helps Force Guide deliver fast feedback to the robot for high-precision part placement.

Mikell Knights, senior staff reporter

Contact:

Epson RobotsCarson, Calif., 562-290-5910,