NPE Booth W6189

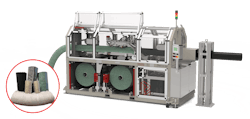

Dreno Covering Baruffaldi’s Dreno Covering machine type TNT/50-200 provides processors a fully automated solution to wrap perforated or slotted corrugated pipes with PP Geotextile, also known as TNT. The machine can be used inline or offline, and can process single-wall rigid and double-wall flexible pipes with diameters ranging from 50mm to 200mm, and it also has been successfully tested with rectangular tubes. The machine wraps the TNT around the pipe and matches the power it feeds to an ultrasonic welding head to the process speed and fabric type to form a continuously welded fabric wrapping around the pipe. Baruffaldi produces downstream equipment for pipe production under its Primac brand.

What’s new? A new version called the TNT-B/50-200. This more budget-minded version is aimed at customers who don’t need the fastest speeds or full automation. The TNT-B/50-200 has a maximum processing speed of about 65.6 feet per minute, and the coil changeover is semiautomatic. The company also has made its TNT scrap-cutting system an option, as some customers don’t require that function.

Benefits Greater flexibility. Baruffaldi said it can offer machines to match customers’ specific production needs, including processing any type of geotextile. The company also has boosted the speed of the TNT/50-200 above its previous speed of 98.4 feet per minute. The TNT/50-200 holds two fabric coils, and can automatically change over to the reserve coil to avoid halts in production.

Baruffaldi Plastic Technology USA Co., Johnson City, Tenn., 423-480-4517, www.baruffaldiusa.com

David Tillett | Associate Editor

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.

Censco acquiring MuCell Extrusion Technology

KraussMaffei now building extruders in U.S.

Nordson names regional sales manager