Never let success overwhelm your business

California molder Scientific Specialties Inc. (SSI) was already expanding its business to keep up with demand for products used in testing laboratories when the COVID-19 pandemic unleashed a deluge of additional orders.

Within three months, SSI purchased seven new Arburg presses and five Sepro robots, commissioned five molds and expanded its Class 100,000 clean room to accommodate the new equipment. Total investment was more than $3 million.

“We have been slammed by work related to the coronavirus and are shipping testing product all around the globe as fast as we can make it,” said Anthony McCracken, VP of product development, in June.

Read how the company handled an immediate tenfold increase in demand for some of its products.

https://www.plasticsmachinerymagazine.com/21136434

Has Zoom become the new normal?

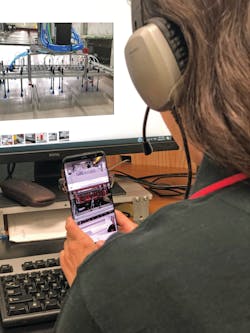

One thing the pandemic has taught us is that business can be conducted via Zoom and other online platforms. Sales calls, conferences and strategy meetings are now no-brainers. But what about installing new processing machines? That too.

GN Thermoforming, based in Nova Scotia, faced travel restrictions when a customer in Russia needed its new thermoforming machines installed immediately. If technicians traveled to Russia for the installation,they would not be allowed to return to Canada.

The machinery manufacturer ended up using WhatsApp Messenger, a freeware, messaging and Voice Over Internet Protocol service owned by Facebook.

The installation, which normally takes GN Thermoforming technicians three to four days on-site, took about one week as they guided the customer’s technicians through the process.

Despite the language issues, the remote process was a success and GN Thermoforming has used it to install several other thermoforming machines around the world.

https://www.plasticsmachinerymagazine.com/21143874

Welcome to the party

Alphamac, an Italian manufacturer of extrusion blow molding machines, entered the U.S. market. The company, which was launched in 2019, offers six all-electric machines in single- and double-shuttle models.

Over the past year, Alphamac said it sold three of its energy-efficient machines to customers in Russia, two to customers in Dubai and two to customers in France.

In May, the company was negotiating the sale of three machines in the U.S., according to a spokesman. Alphamac has formed a partnership with Jackson Machinery, Port Washington, Wis., for sales and service support. It also is considering opening its own office in the U.S.

https://www.plasticsmachinerymagazine.com/21131675

Processing machinery keeping up with new materials

Every extruder manufacturer has stories about odd materials someone has wanted to run through their machines, but Coperion has a great success story with a system it designed to process lignin for a new biomaterial.

Lignin, a byproduct of the pulp and paper industry, is being used to make RenCom’s Renol, which can be blended with virgin or recycled plastic. RenCom plans to produce about 1,000 tons a year in Sweden. Renol is expected to be on the market in 2021.

Germany-based Coperion designed a complete extrusion system consisting of a ZSK Mv Plus-series co-rotating twin-screw extruder, gravimetric feeders, a strand pelletizing system and a lignin bag-dump station.

https://www.plasticsmachinerymagazine.com/21148031

Previous installments of our look back at 2020:

https://plasticsmachinerymagazine.com/21162137

https://plasticsmachinerymagazine.com/21160771

Censco acquiring MuCell Extrusion Technology

KraussMaffei now building extruders in U.S.

Nordson names regional sales manager