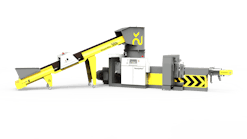

RS class shredders Untha’s RS class of shredders is capable of handling a wide range of materials, including plastic containers, plastic bottles packaging and white goods. They feature a patented four-shaft cutting system that can be customized to the input material, and Untha’s Eco Power Drive stops the cutting shaft as soon as non-shreddable material is detected to prevent damage to the cutting system.

What’s new? An advanced generation of Untha’s RS class of shredders including models RS30, RS40, RS50, RS60 and RS100, two of which Untha displayed at IFAT 2024 in Munich. The new generation features a more solid torsion-resistant construction for added machine longevity, and an LED strip light displays the shredder’s operational status. Custom hopper colors are also available.

Benefits Improved throughput and reduced clogging, thanks to adaptations made to the cutting system symmetry. The electronics have been improved, and the enhanced touchscreen display has been redesigned with an intuitive interface that makes error diagnosis and resolution easier. The new RS shredders include an integrated quick-change screen system that makes screen changes 30 percent faster, and noise levels are also 8 percent lower. Service and maintenance access is also easier, which improves the working conditions for the operator while decreasing downtime.

Untha Shredding Technology America Inc., Hampton, New Hampshire, 603-601-2304, www.untha-america.com

David Tillett | Associate Editor

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.

Rapid Granulator names new sales agents

PLASTICS adds to leadership team