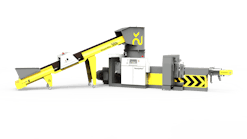

3C Gneuss’ new rotary feeder allows recyclers to process low-bulk-density materials. A conveyor belt feeds shredded reclaim material into the hopper, where a fast-rotating disc with knives cuts, compacts and pre-conditions the material. The knives add energy into the material and start the heating and degassing process before the material is automatically fed into an extruder for recycling.

What’s new? The feeder, which Gneuss demonstrated at the K Show. Developed as part of the company’s first turnkey recycling lines, which also include the company’s extruders and melt filtration systems, the feeders also are available as stand-alone technologies. The recycling lines, known as the Omni recycling lines, have hourly throughputs ranging from 300 pounds to 4,000 pounds, depending on the extruder customers select for their setup.

Benefits The feeder’s ability to handle low-bulk-density materials like fiber waste, film waste and foam.

Gneuss Inc., Matthews, N.C., 704-841-7251, www.gneuss.com/en

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.