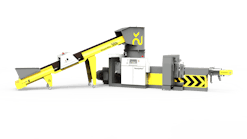

Ampacet adds smaller resin management and blending system

NPE Booth S22097

LIAD Smart BlendSave Compact Ampacet’s automated resin management and blending system is designed to take advantage of limited space and serve up to 10 primary processing machines. It uses patented weighing and blending technology to manage processors’ resin and PCR materials and recipe changes.

What’s new? The blender, which joins the larger BlendSave automated resin management and blending system introduced in 2021. While the original system features up to 40 individual weighing chambers and can serve up to 50 processing machines with a potential throughput of up to 6,600 pounds per hour, the smaller system has a maximum throughput of 3,300 pounds per hour. Like the larger BlendSave, it weighs each ingredient individually for accurate batches and delivers them to the machines using dedicated material lines. It can weigh resin materials of up to 40 ingredients.

Benefits Small footprint, cost-effectiveness and traceability. The new model takes only 6 feet by 6 feet of floor space and is 14 feet high. It has a separate storage and weigh hopper for each raw material, which means no clean-outs or hose switchouts are required, eliminating potential operator mistakes. A centralized control and existing ERP systems allow real-time data management of all resin ingredients every run for the entire operation. This allows total traceability and verification of raw materials in each batch formulation.

Ampacet Corp., Tarrytown, N.Y., 914-631-6600, www.ampacet.com

Bruce Geiselman | Senior Staff Reporter

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.