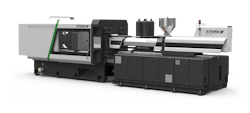

SM-DPV The dual-platen servo-drive injection molding machines (IMMs) in this Industry 4.0-ready line from Chen Hsong — known in the U.S. as CH-America — have clamping forces from about 772 tons to 7,165 tons. The quiet, energy-efficient machines are capable of mold opening and closing speeds of up to about 27.5 inches per second. More than a dozen versions are available.

What’s new? An 18.5-inch touch screen from B&R Industrial Automation, which replaces a controller from another company, along with some improvements involving the hydraulics of the IMM series. In recognition of the changes, made early this year to Chen Hsong’s SM-TP series, which first launched in 2008, the company changed the line’s name to SM-DPV.

Benefits Much faster processing speeds, increased precision and ease of use. The IMMs provide high precision, high stability and high speeds. According to the company, the high-speed advanced CPU provides ample computing power for closed-loop calculations. Plus, the controller is designed to be easy to operate.

CH-America, Torrington, Conn., 860-840-7070, www.ch-america.com

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.