United Soft Plastics targets sustainability with new TPE line

TPEs United Soft Plastics, a manufacturer and custom compounder of TPEs, has developed a new line of TPE materials designed to help manufacturers and brand owners meet their sustainability goals.

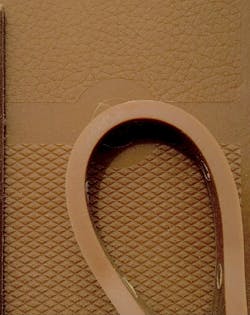

What’s new? Recycled content. Commercially available now are about 10 injection molding grades based on styrene-ethylene-butylene-styrene (SEBS) that contain post-consumer and post-industrial content in amounts up to 100 percent. The resins provide the typical soft-touch, anti-slip properties of TPEs as well as adhesion and haptics. The grades ranging from 45 to 65 Shore A in hardness and are appropriate for a range of consumer product applications, including personal care. Additionally, United Soft Plastics has three other series of sustainable TPEs under development: materials containing up to 70 percent wood flour, rice hulls and/or hemp; biopolymers made entirely of non-fossil-based materials; and hybrid TPEs that combine renewable, post-consumer, post-industrial and bio-based content.

Benefits More options for manufacturers to increase recycled content and reduce the carbon emissions of their products.

United Soft Plastics Inc., Lawrenceville, Ga., 770-339-9362, www.unitedsoftplastics.com