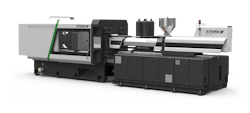

Allrounder T Arburg’s vertical rotary-table injection molding machines are suited for the overmolding of inserts and come in a variety of combinations of injection units and clamping forces. The modular machines can be automated to create complete turnkey systems and feature two-circuit pump technology to ensure simultaneous movements for overmolding. Presses in the line come standard with a combined vertical and horizontal light curtain for operator safety.

What’s new? The Allrounder 1300 T, which features numerous design upgrades from its predecessor, the 1200 T. Arburg redesigned the clamping unit, machine base and control cabinet, resulting in a reduced machine footprint, a larger table and a larger mounting surface for the fixed half of the mold. The company re-engineered the cable routing and made the media connections more accessible. Additionally, the machine is the first to have the Selogica ND control system as standard. The machine is available in two clamping forces: 112 tons and 180 tons.

Benefits Reduced installation space and more room for larger, heavier molds. The new control system makes the press easier to operate, and the cable routing and media connections make setup fast and easy. Furthermore, the company improved the machine’s ergonomics by reducing the height of the table.

Arburg Inc., Rocky Hill, Conn., 860-667-6500, www.arburg.com