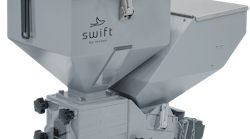

Tumbler separators Dynamic Conveyor has upgraded its line of tumbler separators, which are used to separate injection molded parts from their runners. They are available with two styles of rotating cage: fin and sleeve, in lengths of 2 feet and 4 feet. With an opening for introducing parts that is adjustable from 1.5 feet to 4 feet tall, the separators are suitable for handling parts in a wide variety of sizes. The separators are powered by an energy-efficient, 1/30 horsepower, variable-speed, brushless motor and feature locking casters for portability.

What's new? Recent upgrades, including a frame that is more stable and can be adjusted without tools. The company has made new components for driving the cage that are more durable and reliable. The fins on the fin separator are easier to adjust, and part containment is greatly improved with the new optional shroud. The sleeve-style cages have interchangeable sleeves with custom holes that allow for optimal separation of parts and runners. The sleeves can be switched in and out easily in less than a minute.

Benefits Greater durability and easier adjustment. The simple design has no complicated gear mechanisms to jam or break and provides greater accuracy compared to standard drum separators.

Dynamic Conveyor Corp., Muskegon, Mich., 231-798-1483, www.dynamicconveyor.com