I have been to most of the K Shows during the past 33 years, and I never cease to be amazed at some of the things I see and hear. For example:

HAITIAN INTERNATIONAL Holdings Ltd. was a Chinese company selling molding machines mostly in China when it entered the U.S. market in 2006 through distributor Absolute Haitian Corp. Since then, Haitian has remade itself.

The company delivered 56,000 injection molding machines (IMMs) worldwide in 2021 — up from 43,150 in 2020 — and will likely set another new record in 2022. Sales were $2.5 billion in 2021.

Haitian is adopting a worldwide strategy it calls “2+6 = efficient communications, short delivery routes and high availability.” The 2 refers to two company headquarters, one in Ningbo, eastern China, and one in Shunde, southern China. The 6 describes six regional headquarters in Singapore, Japan, India, Germany, Turkey and Mexico where product development, production and manufacturing take place.

The new strategy is a reaction to recent supply chain disruptions, port congestion and component availability. It includes Haitian developing its own automation, CNC machine tools, die casting machines, drive systems and design services for intelligent production lines and smart factories. Haitian now builds all of its own core components.

Haitian delivered an average of 153 IMMs every day in 2021. That is an astounding number. Even more astounding is how nimble such a large company can be to react to changing market realities.

SUMITOMO (SHI) DEMAG celebrated a milestone in Düsseldorf, Germany, when it handed over its 80,000th electric IMM. It went to TE Connectivity, a Swiss-based manufacturer of connectivity and sensing products. The IntElect 2 S 100/470-110 molding machine will be located at TE Connectivity’s plant in Esztergom, Hungary.

Since 1986, Sumitomo (SHI) Demag has sold TE Connectivity about 500 molding machines. More than half of those presses were all-electric.

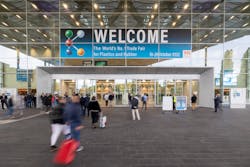

OPC-UA finally achieved wow status at K 2022. The architecture for machines to communicate efficiently with each other was introduced in 2006 by the OPC Foundation and the current version 1.04 was released in 2017. European machinery manufacturers have embraced it.

Forty companies from eight countries scattered across the sprawling Düsseldorf fairgrounds connected 85 machines in a single network using OPC-UA architecture. The demonstration was to highlight Industry 4.0 capabilities.

Visitors could scan a QR code on each machine and view live data about that machine and others on a Universal Machine Technology Interface platform.

There are currently eight OPC-UA standards covering injection molding and extrusion machinery, robots, temperature controllers, LSR dosing systems, hot runners, manufacturing execution systems and material supply systems.

RECYCLING EQUIPMENT manufacturers had a huge presence at K 2022 with plenty of operating equipment, including full recycling lines, for visitors to see. It is a sign of just how important recycling has become to the plastics industry. At one time, there was a question as to whether the industry would embrace recycling. That question has been answered.

“We have been waiting for this show for 40 years now,” said Gerald Breuer, head of marketing and corporate development for recycling equipment manufacturer Erema Group, in a television interview with show organizer Messe Düsseldorf. “It’s the first time that recycling is in the focus of the whole industry. We go from a niche to a must-have.”

Ron Shinn, editor

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.