The year is 1975. Chevy Chase is lampooning President Gerald Ford during the first season of Saturday Night Live. “Jaws” is the No. 1 movie. “The Graduate,” famed in the industry for its reference to plastics, is less than a decade old.

At a pipe and profile extrusion-equipment manufacturer then known as Gatto Machinery, a customer service manager named Artie Riegger has just started his career. Like Bruce Springsteen, Neil Young and Rod Stewart, who were all grooving on the stage in that era, he’s a rocker, too. Fifty years later, he’s still beating the drum for the technologies of the plastics industry, and still passionate about its people.

He’s been with KraussMaffei Corp. since April 14, 1985, and has witnessed the company’s most ballyhooed technologies evolve, from the gravimetric feeding systems and pipe measuring systems it touted 40 years ago to the LRXplus-series robots, powerPrint 3D printer and other innovations it’s brought out in just the past few years.

A few years ago, he spoke excitedly about a project in which he'd helped Amtrol, a subsidiary of steel-products maker Worthington, start its first plastics extrustion line.

The opportunity to work with a clean slate clearly animated him. “This is actually an interesting challenge. ... It wasn’t so much as a sale as, ‘Yeah, we can do this, let’s step up to the plate and make it happen.’ Because don’t forget: It’s one thing to supply the equipment, but you have to also train them.”

That passion for learning still keeps him going, as Karen Hanna, senior staff reporter for Plastics Machinery & Manufacturing, found out in an email conversation with the KraussMaffei Corp. regional sales manager about why he’s not going anywhere.

As he said a few years ago, “This is a hobby to me now. ... I can’t imagine retiring because this is what I do. And I enjoy it. It’s like a painter, or a musician; they’re not going to retire. That’s what they do. That’s what I do here. ... I’m still learning.”

What interested you about the plastics industry?

Riegger: I saw opportunities in the plastics industry.

How did you get into the industry?

Riegger: I began working in service and sales as a customer service manager for Gatto Machinery Development Corp. in Hauppauge, N.Y., in 1975. (Gatto was later sold to [the] Conair [Group]). They designed and manufactured downstream equipment for plastic extrusions (i.e., pipe and profile, etc.), and were located close to my home.

Where has your career path taken you?

Riegger: I joined KraussMaffei (KM) in April 1985 as a regional sales manager for extruders and extrusion lines in the Northeast. I will be with KM 40 years this April.

How have the industry and technology changed and evolved over that time?

Riegger: The industry and technology for plastic extrusion has changed over the years, and KM has stayed ahead of the competition. So many changes have taken place over the last 40 years. Extruder controls are now microprocessors and not only control the extruders but can control the entire extrusion line from gravimetric feed systems, extruders, tooling and downstream.

What do you think the most remarkable changes are?

Riegger: KM’s “Quick-Switch” systems, which allow customers to change pipe diameters (within certain ranges) on the fly. Internal Pipe Cooling (IPC), which could allow shorter cooling lengths, product measurement controls for pipes and sheets. The list goes on and on.

What technologies do you think will be most impactful in the future?

Riegger: AI, which will allow extrusion lines to function without operators online. Recycling systems will grow significantly. Both will be discussed and presented during our TecDays, [which are] March 25-27 at our new facility in Laatzen, Germany. (The company will demonstrate AI capabilities on March 26.)

Where do you think the industry is headed?

Riegger: There will always be a demand for extruded plastic products. New materials and end uses will [result in] new products for new end uses. The industry may go through some difficult times for various reasons.

What are the most significant challenges facing processors?

Riegger: The workers in plastics extrusion industry have been aging since the 1970s and 1980s with many retiring.

I see it is becoming difficult to hire and develop processing technicians to operate extrusion lines KraussMaffei has developed.

I believe that luring new people into the plastics industry will be a challenge. The days of “The Graduate” and the term “Plastics, my boy” are no longer enticing. Many people have retired from the industry from the 1970s, 1980s and 1990s. I really do not know how to lure extrusion line operators into extrusion plants. It’s been proven time and again that a company’s best investment for long-term growth is its people. Workers need to be taken care of by providing them with decent pay, decent working conditions and growth-potential opportunities.

How can processors address that challenge?

Riegger: Training of new people is key. Incentives have to be created. Not everyone needs to go to college and obtain a Bachelor of Science in something. As the electricians, plumbers, welders, etc., now are becoming more-acceptable trades with good-paying jobs and benefits, so do the processors, maintenance and QC personnel in the plastic extrusion industries deserve the same type of recognition.

How can the industry adapt to the needs of new workers?

Riegger: As new automation for extrusion comes more into play, the jobs will become more interesting, the pay should be getting better, and the benefits should be getting better. After all, a company’s best investment should be [its] people for long-term growth and profitability.

What are some of the benefits you think younger people should know about the industry?

Riegger: Plastic extrusion is not going away. There are plenty of opportunities.

What keeps you interested in working?

Riegger: People!

I am still learning! Just when you think you have seen it all, something new comes along. I am always seeking new opportunities for new trends and products.

I still see new opportunities within the plastic extrusion industry with KraussMaffei. During my employment with KM, I was fortunate to have the opportunity to also work as product sales manager for PVC sheet extrusion in 1997.

There was no market for cellular PVC exterior house trim. Up until that time, exterior house trim was mostly wood. Together with one particular customer, we developed the cellular PVC trim market for home exteriors. I then increased the market with several additional customers to meet consumer demands.

Our three largest customers for this product were supplying Home Depot, Lowe’s and major building supply companies. They often could not keep pace with product demand. Hence, they (and others) continued to purchase complete extrusion lines from us. KM supplied complete free-foam PVC sheet lines. These consisted of our largest KMD 164 extruder, gravimetric feeding systems, sheet dies, vertical roll stacks, cooling roller conveyors, haul-offs, cross-cut saws and sometimes stacking systems.

For some reason, the cellular PVC exterior home trim market is still only east of the Mississippi [River]. So, the market will likely continue to grow.

How have you changed or improved your working style or techniques?

Riegger: I have had to change with the times. Although I still visit customers, I realize they are very busy, and their time is often limited. Most of my existing customers and new prospects often prefer virtual Teams meetings. This allows the customers’ people at different locations to communicate with the suppliers’ people at different locations. Drawings and quotes can be viewed and discussed, as well.

What do you like to do outside work?

Riegger: I was a drummer in a rock ‘n’ roll band for 55 years. Now, I enjoy activities with my 15 grandchildren [ranging from 10 to 26 years old], who live within a 15-mile radius of my home on Long Island.

What kind of rock ’n’ roll did you play, and what musicians did you emulate?

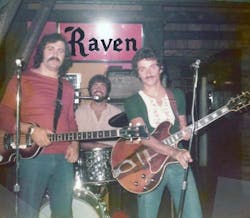

Riegger: Classic rock leaning towards rhythm and blues. The Allman Brothers, Rolling Stones, Beatles. We started as the Vistones in 1964, then changed to the Poor Boys in 1966, and as we got older, we changed our name to Raven in 1975.

We basically appeared on Long Island and [New York City]. We played at the New York World’s Fair in 1965 in the [New York] State Pavilion (still standing, later used in “Ghostbusters.”) That was the largest crowd we played for.

When did you quit drumming?

Riegger: December 2016, only because I did not want to lug around all the drums, cymbals and the stands.

Any fun stories from your time playing rock 'n' roll?

Riegger: Too many to mention, some I shouldn’t mention.

How long do you expect to keep working?

Riegger: I love my job and the mind activity it provides. I work with good people, and my customers and their projects are interesting. As long as I am mentally able, I would enjoy continuing to work.

Just the facts

NAME: Artie Riegger

WHO IS HE: Regional sales manager for extrusion for KraussMaffei Corp.

AGE: 70-something

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.