NPE Booth W5488

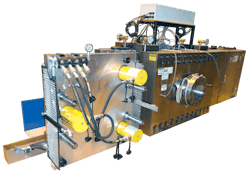

Model CF-1570 continuous filter Berlyn ECM’s 15-inch continuous filter can handle many applications, including recycling operations, and the production of blown film, PVC profile and fiber extrusion. The company described one application in which the CF-1570 processed 17,000 to 20,000 pounds per hour of a bio-polymer, filtering particles ranging from 25 microns to 60 microns.

What’s new? Automated filter plate separation. As the CF-1570’s filter plate passes through the body supporting the filter media, the exiting filter plate hits a proximity switch. This activates the plate separator’s hydraulic system, which continues to separate the interlocked filter plate and pushes the filter plate onto the separator table. This allows the operator to remove the filter plate from the filter and prep it to be put back into the filter, to start the process over again.

Benefits Improved ease of use, efficiency and operator safety.

Berlyn ECM Inc., Worcester, Mass., 508-852-0040, www.berlyecm.com

Vital Statistics

|

Open area |

62 square inches |

|

Throughput |

15,000 to 30,000 pounds per hour |

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.