ZS-B Megafeed Recycling lightweight, high-volume fiber and flake materials can be a difficult task, with low throughputs; in some cases, materials offer such low returns that they are considered not worth the effort of recycling. The latest feeder from Coperion addresses these problems.

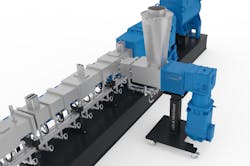

What’s new? A new version of Coperion’s ZS-B side feeder, the ZS-B Megafeed. This new feeder can reliably feed much larger quantities of these lightweight materials into Coperion’s ZSK twin-screw extruders.

Benefits More efficient production, and the ability to process material previously not considered recyclable. For mechanical upcycling processes, flakes and fibers can be fed directly from the ZS-B Megafeed into a ZSK extruder, eliminating steps such as compacting, melting and agglomerating, which lowers investment and energy costs. Using the example of a ZSK 58 MC18 extruder, the company said a ZS-B Megafeed feeder is able to boost recycling throughputs of PA fibers from 154 pounds per hour to 2,204 pounds per hour. The ZS-B Megafeed can be retrofitted to existing Coperion extruders, greatly increasing their throughput rates.

Coperion K-Tron Salina Inc., Salina, Kan., 785-825-1611, www.coperion.com

Vital Statistics

| Traditional throughput (pounds per hour) | With ZS-B MEGAfeed (pounds per hour) | |

| PA fibers | 154 | 2,204 |

| Carbon fiber materials | 110 | 1,543 |

| Multilayer film flake | 176 | 2,866 |

David Tillett | Associate Editor

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.