Energy Recovery: High costs of energy drive recovery innovations

The generally high cost of energy worldwide is a driver of innovations designed to capture and reuse energy expended by injection molding machines. While U.S. molders enjoy lower-than-average power costs, they can still reap the savings of new and enhanced systems from machinery suppliers based overseas.

NIIGATA

Niigata updated its energy-recovery technology with a third-generation system that stores more energy, and a new power module for it that handles energy more efficiently, said Peter Gardner, GM and VP of sales.

The newest regenerative system is implemented as standard technology with the introduction of Niigata's MD S6000 line of all-electric machines, and is now installed on the company's MD S7000 generation of all-electric machines, introduced at NPE 2015, Gardner said. A new power module/amplifier, designed to improve energy consumption, updates the energy-recovery system on the MD S7000 line. For the first time, the new system provides an energy-data-monitoring function.

Japanese manufacturers have been concerned with energy and the costs of power for a long time, according to Chris Unseth, regional sales manager. An informal web search of current electricity costs around the world showed energy in Japan cost an average of 26 cents per kilowatt hour (kWh), compared to 13 cents in the U.S. The high cost of power drives Japanese injection molding machine makers to explore all aspects of energy conservation, including energy recovery, Gardner and Unseth said.

"Being able to capture all aspects of energy data is useful, like knowing how much power is needed to run a particular injection mold. That data can be combined with other data, like labor or resin usage, to find the true costs for running that mold. The molder can learn how much energy it costs to run a mold and whether they can make a profit or not," Gardner said.

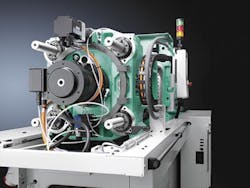

MD S7000 machines use a separate servo-motor drive and amplifier for each major axis of motion, which allows for braking energy to be captured from each servo motor. "Niigata incorporates a motor for every movement of the machine, one, or sometimes, two motors each for injection or the clamp, depending on the size of the machine, and one motor for charging and one motor for the ejector," Gardner said.

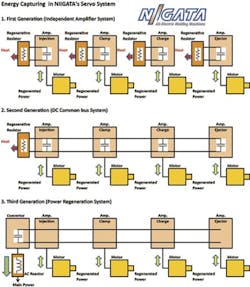

The original configuration of Niigata's regenerative energy system kept the recovered energy from each motor separate. Under the original layout, which may be the most common configuration for regenerative systems, each servo motor has its own energy-storage unit, called a capacitor or condenser, Unseth said.

The third-generation regenerative system incorporates a new technology, an AC converter, which acts as a single, large capacitor for storage of the regenerative energy captured by all the amps and motors. In this design, "the energy is converted by the AC converter as required and distributed to the motors that need power. If the AC converter is full, any additional regenerative DC energy is converted to AC by the converter, then cleaned in a component called the AC reactor, then sent back to the main power to be used by any machine components," Unseth said. The first iteration of the system lost energy if energy-storage units were full; the second-generation systems had linked storage capacity for energy, but still released excess energy once all amplifiers hit capacity.

Also, compared to earlier iterations, the third-generation amplifier can now determine the energy needs of the servo motor, and can play a role in converting regenerative energy to stored energy and then reconverting that energy for system use. The new power module added to the MD S7000 series, called the MR-J4 AC servo amplifier, replaces the MR-J3 amplifier and improves energy-return efficiency, and the third-generation amplifier can store more energy.

In addition, for the first time, the user can monitor energy consumption and integral power consumption of the machine on the machine controller. The amount of recovered energy is not shown on the monitor; rather, the molder is able to view what Niigata calls a "regeneration ratio." The regeneration ratio refers to the ratio of recovered energy compared to the maximum capacity of recovery, Unseth said.

Niigata has found other areas in its machine design that offer opportunities for energy recovery. For example, on MD S7000 machines, the bolts that seal the head of the barrel of the injection unit are flush to the body of the barrel. "When the bolts are sticking out, it creates a radiating effect, and this can create a thermal imbalance when the barrel and nozzle come into contact with the mold," Gardner said.

By mounting the bolts flush to the barrel, heat dissipation in the area where the barrel contacted the mold dropped by 60 percent on a machine with a 35mm screw, he said. Energy usage dropped from 127 watts in that area to 51 watts. The new bolt design conserved energy, delivered a more consistent temperature in the nozzle area, and improved control of nozzle temperature, which eliminated cold slugs and drooling, Gardner said.

NISSEI

Nissei developed a new energy-recovery system for use with NEX-IV, its latest generation of general-purpose, all-electric injection molding presses. The NEX-IV series, being launched this month, will have clamping forces from 33 to 396 tons, although only machines with clamping forces of 196 tons and up will feature the new system as an option, marketing manager Mac Otsuka said.

The energy-recovery system adds another level of energy efficiency to injection presses that already utilize servo technology, Otsuka said. Initial testing has already shown that the regenerative system can have a significant impact on energy consumption.

The NEX-IV line will feature four servo motors, each responsible for driving a main machine movement (injection, metering, mold movement and ejection). Each servo motor receives power from a servo amplifier. Each servo amplifier is equipped with a high-capacity condenser/accumulator that stores captured power and supplies it in a stable manner.

Nissei's system has a fail-safe in case the energy collected during motor deceleration exceeds the capacity of the accumulator. "Electrical current is sent to a power-generation device, then a current-suppression reactor for rectification. The energy is then returned to the commercial power source or factory power," Otsuka said.

"Conventional regenerative systems use a regenerative resister which converts the excess energy to heat. However, the amount of that heat, now wasted energy, can heat the air surrounding auxiliary components serving the injection unit, and this could hamper the performance of those components. This regeneration system is designed to minimize that energy loss," he said.

The effectiveness of the system was revealed in a demonstration by Nissei, in which a NEX220IV model with 243 tons of clamping force ran a dry cycle time of 5 seconds, supporting a 1,056-pound mold. The all-electric model, already designed for energy efficiency, consumed 4.34 kWh, when the regeneration system was off and excess energy was transferred to a resistor and released as heat.

When the regeneration devices in the system were activated, the energy consumption of the machine dropped to 1.47 kW, or a difference of 2.87 kWh. If the machine ran 20 hours a day at the electric cost of 15 cents per kWh, the machine would save $258 per month, Otsuka said.

In addition, the machine incorporates linear guides on the clamping side that reduce friction, allowing for more energy to be captured during deceleration.

A core component of Nissei's system is the servo amplifier, which powers the servo motor, directs the recovered energy to and from the accumulator, and sends surplus energy to the power generation device for return to the main power. The amplifier determines what the power needs of the motor are, and monitors energy usage.

ARBURG

Arburg, a maker of presses with all-electric, hybrid and hydraulic drive systems, has offered braking-energy-recovery systems since 2001. In general, all new Arburg Allrounder machines are equipped with efficiency class IE3 electric motors and drives that provide multistage or stepless control, resulting in energy consumption that is adjusted to the actual power requirement.

"The topic has been treated in a comprehensive and global manner and has been enshrined in the corporate philosophy for many years. There is no fixed figure [as to how much regenerative energy a recovery system captures] as the energy amount always varies depending on the process," said Süleyman Akseven, application engineer.

Braking energy captured from Arburg's machines is temporarily stored in a capacitor, then used to drive the primary movements of the machine. The regulated electric drives also collect waste heat in their water-cooling system and can transfer it to a component that requires power, Akseven said. The liquid-cooled servo motors of electric Allrounder models can feed captured energy back to the factory's power grid for use by another machine in the factory, or it can transfer the energy back to the utility supplier.

Other energy-saving features of the Allrounder models include a Selogica control function that can be used to automatically switch on, switch to standby or automatically lower the plasticizing cylinder temperature. The control function also deactivates motors and heating when the machine is at a standstill.

ENGEL

An energy-recovery technology from Engel captures braking energy from the injection molding machine's servo motors into a large-capacity, kinetic-energy storage unit. According to the company, it recovers so much energy that the machines can actually run, in part, off stored energy during periods of peak demand.

The proprietary, high-capacity kinetic-energy storage unit is a component of Engel's energy-recovery system. The system is offered on larger models of both Engel's hybrid e-speed toggle-clamp machines for high-speed packaging applications and its all-electric e-motion series for high-precision optical parts.

Joachim Kragl, director of advanced molding systems and processing, pointed to that as the distinction between Engel's system and other systems designed to recover braking energy. Users of other systems direct power back to the grid, because they don't have the capacity to store enough of it to run their machines.

"[Braking-energy recovery] is essentially a given with the electric drive concept and is considered a technology standard. However, using the servo technology just to send recovered energy back just results in a modest monetary gain. The savings are not significant because the amount of recovered energy is not very high. We are taking a different approach where we reuse the energy in the system to actually reduce the peak [usage] of energy [from the grid], which can bring dramatic savings," Kragl said.

Braking energy from the platen movement is transferred into Engel's kinetic-energy storage device, which applies the power to the servo motors during the following molding cycle. The device is a flywheel that spins at high speeds when energy enters it. An algorithm in the machine control software manages the collection of the recovered energy and its distribution to the various servo motors. The recovery system collects the energy from the motors driving the clamp movement. The same motors governing the clamp movement receive the recovered braking energy the following cycle. Kragl said the recovery system is designed to always collect the maximum amount of braking energy available.

Mikell Knights, senior staff reporter

For more information

Arburg Inc.,Rocky Hill, Conn., 860-667-6500, www.arburg.com

Engel Machinery Inc.,York, Pa., 717-764-6818, www.engelglobal.com

Niigata Machine Techno Co. Ltd.,Wood Dale, Ill., 630-875-0202, www.niigata-us.com

Nissei America Inc.,Anaheim, Calif., 714-693-3000, www.nisseiamerica.com