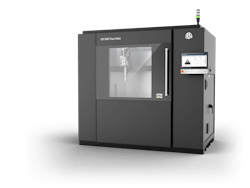

EXT 800 Titan Pellet printer is fast, economical

EXT 800 Titan Pellet 3D Systems has built a line of industrial 3D printers that print with common resin pellets rather than with filaments. The company’s newest printer, the EXT 800 Titan Pellet, is a smaller printer that incorporates the industrial CNC controllers, heated bed and chamber of its larger predecessors. It has a single extrusion tool head, and the company says it is ideal for manufacturing environments, including spaces ranging from offices and labs to larger shop floors. This printer can be used to make parts as varied as functional prototypes, tooling and fixtures, thermoforming molds and end-use parts.

What’s new? The EXT 800 Titan Pellet, which was developed to address customer requests for a printer that can balance their needs for producing smaller parts at a reasonable cost. It can be ordered now, with deliveries expected to begin in the third quarter of this year.

Benefits Speed and cost savings. The company says the EXT 800 Titan Pellet offers print speeds up to 10 times faster than filament-based printers, and offers material at one-tenth the cost. The printer’s smaller footprint and lower upfront cost make high-speed, industrial-grade pellet extrusion more accessible to a wider range of manufacturers. It has an active bed and chamber heating, which allows the use of a wide range of materials, including ones that cannot be printed on filament-based machines. The printer’s compact frame enables it to fit through a standard set of double doors, providing ease of delivery and installation.

3D Systems, Rock Hill, S.C., 803-326-3930, www.3dsystems.com

Vital Statistics

|

Build volume |

31.5 inches by 23.6 inches by 31.5 inches |

|

Available resins |

ABS, PC, nylons, polyetherimide, and polyetherketoneketone, as well as highly flexible thermoplastic elastomer, and TPU |

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.