Riverside Medical Packaging Co. Ltd., based in Derby, England, which makes blister packs, has found a remedy for the headaches it got using other companies' thermoformers — it invented its own.

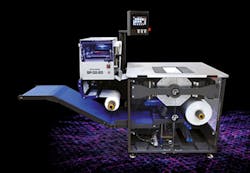

Known as Shawpak thermoformers in Europe, or as SP Thermoforming machines in the U.S., the new, compact formers feature stations arranged around a servo indexing drum, rather than a linear layout. They made their official U.S. debut at Pack Expo in October in Chicago.

"We've taken the concept of a long, linear machine and rolled it into a carousel machine," said Bob Hartwig, the co-founder and managing director of BTS International, which represents the new forming machines in the U.S. The "radical design" results in several benefits: space savings, the elimination of trim waste, reduced energy consumption and fewer maintenance requirements.

The centerpiece of the process is an indexing drum. Like a Ferris wheel with buckets spaced around the diameter at equal distances, the drum has an array of fixtures called facets. Each facet is home to one or more cavities, depending on the application.

The process begins at the 3 o'clock position, where film is positioned into the empty cavity or cavities in the adjoining facet. The machine forms the film by subjecting it to pressurized air and heat from a heating plate in the cavity. It then indexes the wheel, which moves counterclockwise. At the 12 o'clock position, an operator or robot lowers a product or products onto the formed film. The wheel rotates again, and, at the 11 o'clock position, the machine adds lidding material over the forming material. Pressurized air and heat directed into the cavity seal the pouch at the 9 o'clock position.

The machine ejects the fully formed pouch at the 6 o'clock position.

While initially designed for producing packaging for medical parts, such as syringes or surgical gauze, the machines are suited for a range of applications, including making packaging for food for humans or animals. They can be used to manufacture both rigid and flexible packs from any type of plastic film.

So far, eight models are available. Each is named according to the measurement, in centimeters, of its maximum web width and maximum index distance. For instance, the smallest is the SP-22/20, which has a maximum web width of 220mm and a maximum index of 200mm, or about 8.7 inches and 7.9 inches, respectively. It measures about 4.4 feet by 2.8 feet by 3.2 feet, while the biggest model, the SP-62/25, measures about 4.8 feet by 2.1 feet by 3.4 feet.

Machines can be customized so that certain applications are located at stand-alone stations. Depending on customers' needs, the film spools also can be positioned outside the machine. Such configurations can add to the overall width of work cells.

The SP formers take up between about 35 cubic feet and 53 cubic feet. At about 4.5 feet long, they're just half or a fourth the length of conventional thermoformers. Depending on the application, they can produce as many as 300 small, flexible, automatically loaded packages per minute, Hartwig said.

"Our clients are like, 'Wow, that's the whole thing?' " he said.

Inspired by about 40 years of making packaging, Riverside designed the machines to address its own needs, launching them a couple years ago in Europe.

Recently, it's added an optional, outside-the-machine die-cutting station.

Beside saving space, the machines greatly reduce material requirements and simplify maintenance.

"This is what happens when an engineer thinks outside the box, I guess," Hartwig said.

One source of savings comes from the material spools. The machine's size dictates the maximum width of spool that it can run but places no limitation on the minimum width. That's in contrast to most standard machines, which are fixed-width. That means a lot of wasted trim, Hartwig said.

"It's a kind of painful thing that people have gotten used to," he said. By contrast, "we can run any size, any width of film up to the maximum width for that particular machine."

The spools and drums are easy to remove and replace, so changeovers take only minutes.

Riverside Medical offers a number of optional accessories, including printers, light curtains, perforating stations and specialized blades, but Hartwig is most excited about what the company's machines don't have. Since heating occurs only during discrete steps — at 3 o'clock and 9 o'clock — there's no need for chillers. And because there's no film web to pull across the length of a thermoformer, there are no gripper chains — a frequent source of maintenance woes for those who run conventional machines.

There's also no vacuum; cavity heating and pressurized air are sufficient for forming.

With fewer parts, the machines require less maintenance and energy. In fact, they run on single-phase power, rather than three-phase, like conventional formers.

Hartwig, who said he's been aggressively marketing the machines since the summer on behalf of Riverside Medical, got his first order from a U.S.-based customer about a month ago. People, he said, have been both impressed and surprised by the petite packagers.

"People go, 'Oh, it looks like one of those little toy machines,' " he said.

A single machine can't match the throughput of a conventional thermoformer, he acknowledged, but they cost considerably less, meaning users can invest in several.

He cited one factory in Israel, where a number of them are in operation — each as part of an individual robotic cell.

"You can basically fit two or three of our machines in the space of a big machine and outproduce it at a lower cost," Hartwig said.

Karen Hanna, copy editor

Contact:BTS International LLC Franklin Lakes, N.J., 201-961-4740,

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.