Windmoeller & Hoelscher's purging module can be retrofitted to older units

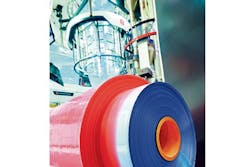

Turboclean Windmoeller & Hoelscher's (W&H) Turboclean automation module is used to purge resin simultaneously from all gravimetric hoppers and extruders in a W&H Varex blown film line. Varex blown film lines are suited for use with a broad range of resins and applications, including films with one, three, five, seven, nine or 11 layers. The photo shows the transition made via a Turboclean module from a blue, 40-micron, five-layer shrink film to a red, 50-micron, five-layer film for food packaging.

What's new? Retrofitting capability. Previously available only on new lines, the plug-and-play module can be retrofitted on Varex lines that were built in 2010 or later.

Benefits Dramatically faster automated product changeovers. Instead of manually purging resin one extruder at a time, the operator simply moves the suction lance from one resin port to the next. Changeovers take as little as 12 minutes versus up to 40 minutes for manual changes.

Windmoeller & Hoelscher Corp.,Lincoln, R.I., 401-333-2770, www.whcorp.com