Conair cutter is ideal for clean rooms

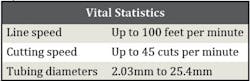

M-TPC Conair has introduced a traveling planetary cutter for small-diameter medical tubing, the latest in the company's Medline series of clean-room-ready, downstream extrusion equipment for medical applications. The device's programmable, servo-driven cutting head precisely controls cutting speed, rate of cutter penetration and final depth of cut. The M-TPC is suited for all types of plastic medical tubing, including PS, HIPS, PET and PC. It features a touch-screen control that can store cutting programs for future use, and allows the operator to set table travel velocity, tubing size, blade velocity and cutting depth.

What's new? The cutter, and its technology. Typical rotary and flying-knife cutters remove material, which can leave particulates behind. The M-TPC splits the tubing apart via displacement, without losing any material.

Benefits Precise cutting with no need for secondary finishing operations such as trimming or deburring. The planetary knife spins around the circumference of the tubing, cutting it without deformation, particulates, burning or fracturing. This method doesn't block airflow through the center of the tube, so tube sizing and ovality are unaffected. Also, the cutter is designed to allow for quick blade changes.

Conair Group, Cranberry Township, Pa., 724-584-5500, www.conairgroup.com