By Michael Machuca, Emerson

While the concept of plastic recycling has existed for many years, only 9 percent of all plastic waste is being recycled globally (Figure 1). Many post-consumer plastics are considered unrecyclable via traditional mechanical methods and are sent to landfill or incinerated.

This is changing as advanced recycling, a collection of emerging recycling technologies, offers a potential solution to increasing the recycling rate of plastic waste. As companies adopt these new technologies to turn plastic waste into valuable feedstock, they are looking for ways to scale up production — while improving yield, efficiency and reliability.

Figure 1: Estimated global plastic waste by waste management category. More than 90 percent of plastic is never recycled.

When we talk about plastic, we’re describing a huge family of products comprising hundreds of specific polymers, virtually all of which stem from the complex and versatile molecules included in hydrocarbons, mostly crude oil and natural gas. For a product designer wanting to use plastic for an application, it is possible to find any imaginable combination of attributes, including mechanical strength, moldability, temperature resistance and dozens of other factors. This wide range of products is one of the main characteristics that makes recycling so difficult.

This article will examine recycling via conversion, a process that returns waste plastic to the source molecules via pyrolysis. Like most recycling processes, conversion focuses on three of the six polymers used most frequently for packaging and similar applications (Figure 2). The most common, as indicated by their recycling number designations, are 1-PET, 2-HDPE and 5-PP. These are also the most recycled. Others, such as 3-PVC, 4-LDPE (low-density polyethylene) and 6-PS, are less common and more difficult to recycle.

Figure 2: Most plastic waste is from packaging that uses a small group of polymers. Fortunately, some of the most-used types are amenable to recycling.

Pyrolysis works with mixed or minimally sorted waste, including the three most common varieties: PET, PP and HDPE. When waste is heated without oxygen in a pyrolysis reactor, solid mixed plastics can be gasified and liquified. The heat applied may be dry, or it can be injected as water and supercritical steam.

In the first case, dry heat breaks down the plastic completely, turning it entirely into syngas, which is a mix of hydrogen and carbon monoxide. Once purified, this syngas can be used as a feedstock for many purposes, including combining it with wood pulp for conversion to cellulosics, which are building blocks for acetyl chemicals and cellulose acetate plastics.

The second approach, using water and steam, allows mixed plastics to be heated to critical temperatures in the presence of a catalyst, breaking down the polymeric bonds to yield short-chain, stable hydrocarbons. With distillation as a separation step, fractions can include combustible gases, various-weight hydrocarbons and even carbon solids.

Fired-heater control

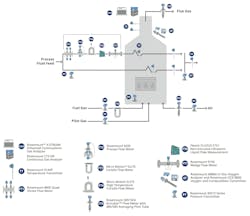

Generally, pyrolysis conversion processes are the most heat-intensive of the advanced recycling technologies, and they depend heavily on fired heaters (Figure 3).

Figure 3: Being able to maintain control and optimize fired-heater performance depends on data from strategic instrumentation with careful analysis.

Controlling a fired heater requires instrumentation covering three process variables: flow, pressure and temperature.

- Flow meters are critical to measure fuel flow. Coriolis mass flow meters provide a more accurate energy flow measurement than volumetric meters. It is important to measure combustion airflow, as well, because it must be controlled to optimize the fuel/air mix. Combined with data from the oxygen and combustibles sensor on the stack, these measurements provide all the variables necessary to fine-tune combustion for maximum fuel efficiency and heat capture. They also should be used on the process fluid feed, along with inlet vs. outlet differential pressure and differential temperature. These variables help calculate overall efficiency, plus they indicate when fouling is forming inside the liquid tubes.

- Pressure transmitters monitoring firebox draft pressure should have advanced diagnostics able to capture the subtle pressure fluctuations characteristic of burner instability, as this data can be used to prevent safety shutdown due to a flameout. All these instruments must send their information to an automation host system, such as the DeltaV SmartProcess Heater, to monitor and optimize operation.

- Temperature sensors are installed at many points, particularly at the flue gas outlet to aid in combustion control and within the heat exchanger system to optimize its operation.

Equipment reliability and safety

The pyrolysis conversion process is considered a severe service and hazardous application due to the high temperatures involved, and the flammability of products coming out of the pyrolysis reactor. Since syngas is flammable, the potential for leakage should be addressed with appropriate safety instrumentation (Figure 4):

- Gas detectors positioned strategically around production equipment can trigger alarms if fugitive gas is present.

- Flame detectors able to detect the radiation from burning gas can respond to a fire in a matter of seconds, activating alarms and fire extinguishing systems.

Figure 4: Areas around the pyrolysis reactor and distillation column should use gas-leak detectors (left, the Rosemount Incus ultrasonic gas-leak detector) and flame detectors (right, the Rosemount 975UR ultraviolet/infrared flame detector).

Recycling units that produce liquid hydrocarbons rather than syngas also must take appropriate safety measures around the distillation column, much like those used in refinery environments since the products are similar.

Maintaining asset integrity is critical because contaminants included in the waste feedstock can create products that cause corrosion, leading to metal loss and leaks from piping and vessels. Manual, periodic metal thickness measurements are ineffective in mitigating corrosion proliferation between scheduled evaluations because of variability in technician skill and exact points of measurement.

New techniques, such as wireless ultrasonic sensors (Figure 5), track metal loss in real-time, giving reliability teams ongoing visibility into asset integrity, along with actionable data to mitigate the risk and impact of corrosion and erosion.

Figure 5: Emerson’s Rosemount Wireless Permasense Corrosion and Erosion Monitoring Systems use ultrasonic thickness sensors combined with Plantweb Insight software to capture and analyze metal loss.

Steam generation and distribution

Steam is used primarily to deliver heat to processes, especially heat exchangers, because it is very controllable and can be highly efficient in that role (Figure 6).

Figure 6: Strategic instruments can control combustion, as well as steam usage when it reaches its applications.

However, the universal problems with steam systems are their high operating costs, potential for inefficiency and high maintenance requirements. Here are two simple solutions that can result in major steam system cost savings.

Steam consumption monitoring

Many steam distribution systems are wasteful because there is little or no indication of how much steam is going to each application. Determining where problems exist requires accurate flow measurement in each area, and even in individual applications that use large amounts of steam. Fortunately, this type of measurement is now easier using vortex technology.

The Rosemount 8800 multiVariable vortex flow meter is particularly well-suited to steam service because it can compensate for changing fluid density by measuring temperature and pressure. With an operating temperature range of minus 40 degrees Fahrenheit to 800 degrees Fahrenheit, it can cover most typical steam applications. When steam distribution is measured in detail, it is possible to identify and fix steam hogs and leaks, reducing overall consumption and saving fuel costs.

Steam trap monitoring

When steam is used with a heat exchanger, it generally condenses back into water that must be removed from the steam line. As steam cools, condensate accumulates in the pipe, and it needs to be removed to prevent water hammer, which can damage equipment. Such situations call for a steam trap, an automatic valve designed to separate and remove condensate without releasing live steam. How well steam traps perform affects the efficiency and sustainability of the entire steam distribution system. Steam trap service is harsh, so eventually the mechanisms often fail. Therefore, they must be checked frequently to ensure correct operation.

Since manual checking isn’t always practical, an acoustic sensor can be mounted permanently on the piping adjacent to a steam trap (Figure 8) to sense its operation continuously. Such sensors are internally powered with a battery and use WirelessHart networks, and they can send data to maintenance departments so repairs can be made to minimize wasted steam from traps stuck open. These devices can be mounted with hose clamps with no process penetrations, so there is no need for a shutdown.

Figure 8: Emerson’s Rosemount 708 Wireless Acoustic Transmitter can be mounted adjacent to a steam trap, where it senses activity and measures temperature. It sends this data to Plantweb Insight for aggregation, analysis and presentation via a dashboard for an overall performance picture.

Conclusion

Partnering with a supplier able to provide a complete portfolio of automation solutions, together with extensive domain expertise, can help to reduce project complexity and drive operational efficiency, while maximizing plant safety and reliability. Emerson’s automation technologies are designed to optimize plastic recycling units by delivering precise control, increased process visibility and actionable information for improved decision-making.

All figures courtesy of Emerson

About the Author

Michael Machuca

Michael Machuca is the chemical industry marketing director for the measurement instrumentation portfolio at Emerson. He has been with Emerson for over 18 years in various product-management and marketing roles supporting industrial process-measurement applications in the oil and gas and chemical industries. Machuca holds a Bachelor of Science degree in mechanical engineering from the University of Houston.