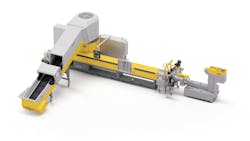

C:Gran Particularly suited for moist materials with low bulk density, this NGR series of cutter-compactor-extruders can be used in the recycling of flakes, films or regrind. Shredding, homogenization and drying and heating of the plastic take place in the cutter bin, and specially arranged feeders provide additional compaction. Centrifugal force and the feeders convey the prepared material to the extruder screw. The C:Gran models come in a variety of sizes and styles, with hourly throughputs ranging from 1,210 pounds to 6,610 pounds. Depending on the application, the machines can be equipped with a wide range of melt filters, such as continuous filters, piston filters or backflush filters, as well as other add-ons, such as a variety of degassing or venting options, a roll feeder or conveyor unit.

What’s new? Numerous updates since the C:Gran debuted in 2012. This year, NGR has added to the portfolio, bringing to eight the total number of models available. The machines feature a new Auto-Pilot control system that automatically adjusts the cutter-compactor, extruder and pelletizing speeds. They also have a shorter processing unit with the option of adding a second filtration stage as needed. For customers that need enhanced drying or degassing performance, the machines can be specified with a new Dry-Boost feature or Cascade option with a Power Venting section.

Benefits The ability to handle moist material, with water content of up to 12 percent, thanks to the heating of the plastic in the cutter bin. When combined with a twin-screw extruder, the system performs recycling and compounding functionalities all in one step. The systems’ extruder screw technology allows gentle, optimal melting even at high throughput rates, and the machines produce pellets of a uniform size well-suited for subsequent extrusion and consumer uses. The Auto-Pilot system guarantees reliability, process stability, quality and efficiency.

Next Generation Recycling Machines Inc., Atlanta, 678-720-9861, https://ngr-world.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.