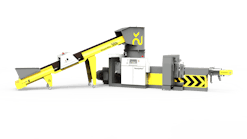

AXP Bay Plastics Machinery (BPM) pelletizers — also known by their longer name, the A-Series X-Class pelletizers — can chop a wide range of thermoplastics, including rubber-like materials and brittle, fragile and glass-fiber-reinforced materials. They are designed to be compact and resilient, capable of continuous use in extreme conditions. They allow tool-free access for maintenance.

What’s new? The AXP (HD) line of heavy-duty pelletizers, modeled off the larger-model versions of the AXP12 and AXP16. The more-robust AXP (HD) pelletizers have been designed to handle heavily filled and difficult-to-cut material. They have a few larger components — including motors, feed roll air cylinders for greater clamping force, and diameter rolls and bearings that reduce deflection. Options include a gearbox that lets users engage both upper and lower feed rolls, and a rotor coupling drive that allows the rotor to remain free of belt load with higher horsepower. Pelletizers’ capacity depends on material input, but users have reported to BPM that they can handle 100-140 pounds per hour of nylon materials, and about 50 pounds per hour of PP materials. Filled materials have dramatically different rates.

Benefits Consistent results and more robust cutting, making the AXP (HD) pelletizers appropriate for new engineered resins, including heavily filled glass-reinforced materials. The pelletizer’s push-pull bed knife holder allows users to adjust the bed knife gap to be consistent all along the entire width of the cutter.

Bay Plastics Machinery, Bay City, Michigan, 989-671-9630, https://bayplasticsmachinery.com

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.