Erema system processes challenging post-consumer materials

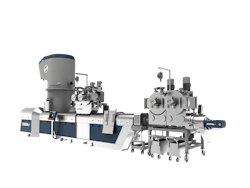

Intarema TVEplus DuaFil Compact Designed for recycling post-consumer materials, Erema’s double-filtration technology combines the patented Intarema TVEplus extrusion system for processing challenging materials with Erema’s new DuaFil Compact Technology, which provides subsequent high-performance filtration and an upstream reduced-temperature pressure-build-up zone.

What’s new? The two-technologies-in-one system. It features a melt pump custom-designed for the applications, allowing the pressure buildup required for the second filtration to be especially efficient, at a relatively lower temperature. Because the extruder does not need to build up pressure, it can be much shorter than previous Erema double-filtration systems.

Benefits The ability to recycle challenging post-consumer materials — even material streams with varying degrees of moisture and contamination — with significantly reduced energy consumption. The machine provides consistently gentle treatment of the melt throughout the entire extrusion process. The lower melt temperature of the DuaFil Compact has a positive effect on the melt quality and reduces energy consumption by about 10 percent. The new technology achieves a melt temperature upstream of the second filter unit that is 33.3 degrees Fahrenheit lower than the previous Erema double-filtration solution when processing LDPE film containing paper; by operating at a lower temperature, it avoids combustion, which would otherwise cause odors or discoloration. Recycled pellets produced by the technology could allow manufacturers to increasingly replace virgin material with recycled material in end products. Though focused with the technology on PE film recycling, Erema also anticipates applications involving PP flexible films.

Erema North America Inc., Ipswich, Mass., 978-356-3771, www.erema.com/us/home/