Patent Report: Washing system removes metal from plastic flakes

Washing and separation. The U.S. Patent and Trademark Office has awarded a patent to Previero N. Srl, Lissone, Italy, for a system and method for washing plastic flakes that is more efficient at removing metal contamination than previous technologies. According to the patent, the invention also is structurally and functionally simpler than traditional systems; produces more usable recovered plastic; and uses less washing fluid and energy.

Hydrocyclone units are often used to separate post-consumer plastic pieces from heavy contaminants such as metal. The vortex the units generate causes the plastics to separate from the contaminants, which drop to the bottom of the tank. However, such systems may not remove contaminants that adhere to the plastics, requiring the use of a washing unit downstream. This setup also can be structurally and functionally complex to create and manage.

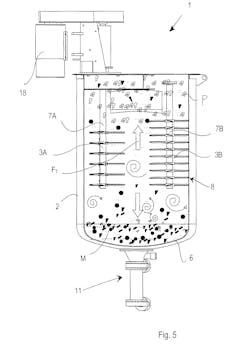

The apparatus described in the patent features a washing container with an inlet and an outlet, as well as at least one vertical rotor-shaft with a series of impeller units mounted one above the other. Each impeller unit comprises a group of blades that are tilted in the opposite direction from the blades of the impeller above or below it. The blades create a turbulent stirring action to mechanically remove contaminants from pieces of plastic that are in a washing fluid.

“The tilt of the blades and the rotation speed of the stirring device are chosen carefully to generate an upward thrusting action to maintain the plastics material with a specific weight that is greater than the specific weight of the fluid in a floating condition,” the patent states. “The plastics material is retained inside the container for sufficient time to obtain a desired degree of purity and decontamination for the plastics material, after which it is evacuated by controlled overflow.”

The method and apparatus “enable high levels of purity to be obtained in the recovered plastics material in reduced time, owing to the immediate continuous removal of the contaminants from the washing container,” the patent states.

Patent 11,179,729; issued Nov. 23