NPE Booth W3921

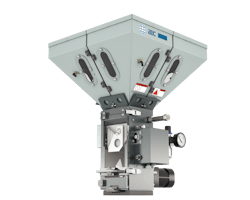

BD This series of AEC gravimetric batch blenders is appropriate for injection molding, extrusion, blow molding and other processes. Exact specifications can vary by model, but, generally, the blenders feature quick-acting diamond slide gates, unique mix chambers, and an easy-to-use high-resolution color touch-screen interface. They can dispense as few as five pellets per pulse.

What’s new? The BD-100, which joins the ranks of larger models introduced earlier: the BD-500, BD-900, BD-2500, BD-4000, and BD-6000. It has a 1-pound batch size and feeding accuracy of within 0.1 percent over time for each material fed into the batch; it also has a precision 0.01-percent span accurate load cell weighing system.

Benefits Ease of use and efficiency. The blenders provide optimum mixing and blending consistency, and feature an easy-to-clean, ergonomic design, and require no tools for maintenance. According to AEC, they are durable and reliable.

AEC, New Berlin, Wis., 262-641-8600, www.aecinternet.com

Vital Statistics

|

Model |

BD-100 |

BD-500 |

BD-900 |

BD-2500 |

BD-4000 |

BD-6000 |

|

Maximum hourly blending rate with three components |

100 pounds |

500 pounds |

900 pounds |

2,500 pounds |

4,000 pounds |

6,000 pounds |

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.

Request More Information