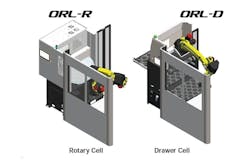

Okuma Robot Loader (ORL) The three units in Okuma’s new automation line can load and unload workpieces from both new and existing Okuma machines. All are equipped with industrial robots from Fanuc, with grippers that can hold a payload of up to 25 pounds. They include the ORL-D, or Okuma Robot Loader – Drawer, which is a drawer-style workpiece storage unit with a standard template that holds up to 92 workpieces. An optional template can hold up to 180 smaller workpieces. The ORL-R, or Okuma Robot Loader – Rotary, is a disc-style workpiece storage unit with a variety of template options that can hold up to 166 workpieces. The ORL-MC, or Okuma Robot Loader – Machining Center, is a workholding and workpiece storage unit for up to 288 workpieces. It can handle multiple part numbers in high-mix, low-volume manufacturing environment.

What’s new? The ORL series, which made its debut in September at the International Manufacturing Technology Show (IMTS) in Chicago.

Benefits Efficient, seamless loading and unloading of workpieces. The ORL products are compact, requiring between 8 and 9 feet of floor space.

Okuma America Corp., Charlotte, N.C. 704-588-7000, www.okuma.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.