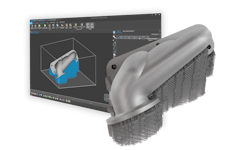

e-Stage for Metal+ Materialise’s e-Stage for Metal software is a module for Magics, the company’s data and build preparation software that optimizes data and build preparation for 3D printers that perform laser powder bed fusion (LPBF). The software can be used to build a wide range of parts, including for molding applications. While LPBF is a leading technology for additive manufacturing, it is also one of the most complex technologies to use, and a survey commissioned by Materialise found that two main factors restraining companies from adopting 3D printing are a lack of knowledge and the cost associated with the production process.

What’s new? e-Stage for Metal+, an update to the original module. It uses physics-based modeling to calculate where deformations will occur in the 3D printing process, and automatically generates supports — which can be needle-thin or cone-shaped — to where they are needed.

Benefits Streamlined data preparation. By automating support generation, users can spend up to 90 percent less time on support design. Appropriate application of the two support types optimizes stability and heat distribution during the 3D printing process, avoiding part deformation and reducing post-processing efforts. In addition to automating steps, e-Stage for Metal+ lowers the learning curve, allowing users to connect the software to any machine and quickly optimize support generation. It also helps lower iteration rates, making metal additive manufacturing more economically viable.

Materialise USA, Plymouth, Mich., 734-259-6445, www.materialise.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.