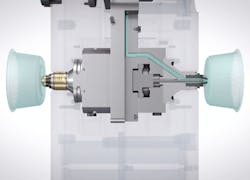

Compact stack mold Oerlikon HRSflow has developed a new compact stack mold for processing thin-wall packaging from post-consumer recycled resins and other sustainable compounds. The company’s Test Lab has a demonstration tool equipped with the new technology that customers can use to run product trials with their most challenging polymers. The demo tool has been designed to produce 210-milliliter single-serving cups from recycled PP; each weighs 6.3 grams and is 0.3mm thick.

What’s new? The patent-pending compact stack mold system, which the company said will be available in the fourth quarter of 2023.

Benefits Fast injection and cycle times. The system fits a maximum plate thickness of 220mm and a minimum distance of 260mm from gate to gate of the coaxial nozzles, enabling the use of smaller injection molding machines. The mosaic frame on the part walls, which was patented by Collomb Mecanique s.a.s., Oyonnax, France, ensures a robust structure despite the part-weight reduction. Employing Oerlikon’s new Xd nozzle series ensures a stable injection process and maximal productivity at a lower cost per unit. The mold’s plug-and-play installation simplifies assembly and maintenance, avoiding long and costly downtime.

Oerlikon HRSflow, Byron Center, Mich., 616-228-6900, www.hrsflow.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.