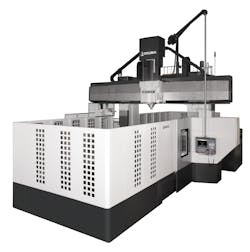

New Okuma machining center boosts productivity

MCR-BV Okuma’s double-column machining centers provide great stability and power, and can be used in a wide range of machining applications. They are well-suited to producing dies and molds.

What’s new? The MCR-BV, the seventh machine in Okuma’s double-column lineup. It comes in three sizes, with X/Y/Z travels of up to 40 feet by 13.8 feet by 2.6 feet.

Benefits Greater productivity. The MCR-BV has a high-torque, high-output integral motor/spindle for powerful cutting that combines with rapid traverse rates for shorter cycle times. Its five-face capabilities mean less setup time is needed. It also offers very accurate cutting, with its Thermo-Friendly Premium feature to suppresses thermal deformation, AbsoScale Detection for highly accurate positioning and 3D calibration for volumetric accuracy comparisons. Accuracy is also aided with its increased spindlehead rigidity, and a table that is 30 percent thicker than the previous model to handle the weight of large workpieces and high cutting forces.

Okuma America Corp., Charlotte, N.C., 704-588-7000, www.okuma.com