Fiber reinforcing. A patent awarded to Kraussmaffei Technologies GmbH, Munich, describes a method and apparatus for producing fiber-reinforced plastic parts.

One necessary step in the process is to apply a powder coating to the fiber strand. Such coatings are needed to prevent agglomeration of the fibers when they contact molten resin. Typical methods such as passing fiber through a powder-air mixture or using a spray gun result in homogenous powder application, but do not allow for precise adjustment of the coating. Therefore, they cannot be used to make parts having a defined proportion of powder on the fiber strands.

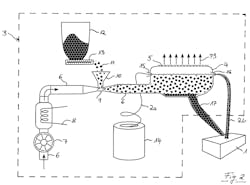

The invention has a chamber that optimizes coating of continuous fibers. An air channel uses a fan to propel ionized air through a heating unit on its way toward the chamber. Prior to reaching the chamber, the air channel enters a Venturi nozzle. Above the Venturi nozzle is a storage container holding powder, which feeds into the Venturi nozzle to be mixed with the ionized air. This powder-air mixture is blown into the chamber, which has an air-permeable membrane along its top that allows incoming air to escape but keeps the circulating powder within.

Continuous fiber strands are drawn into the chamber through an inlet. The fibers can either be grounded or given a charge opposite that of the powder entering the chamber. As the fibers are drawn through the chamber, powder particles are attracted and deposited on the strands.

“With the heating device it is possible to heat the air to a temperature at which the powder particles begin to melt. This improves the adhesion of the coating material to the surface of the fibre strands,” the patent states.

The fiber strands exit the chamber and are drawn into the processing screw or screws of an injection molding machine or extruder. The step of heating the strands also improves wetting of the fibers by ensuring the molten plastic does not solidify on initial contact with the fibers.

“The fibre strands … coated in this way are supplied to the plasticizing device of the machine … and incorporated into a molten plastic material. In this way, a mixture of plastic melt and fibre material is produced and this mixture is subsequently fed to a shaping device.” The shaping device can be an extrusion die or an injection mold.

The patented method thus creates plastic parts reinforced with fiber strands that have been coated homogenously with a defined quantity of powder.

Patent 11,186,025; issued Nov. 30

ABB appoints chief sales officer for B&R

KraussMaffei now building extruders in U.S.