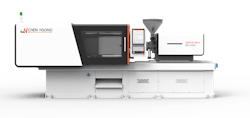

Spark EH and Spark AE Designed primarily for use in clean rooms, these electric injection molding machines (IMMs) from Chen Hsong have clamping forces ranging from about 44 tons to about 441 tons. The Spark EH line is electric, with hydraulic ejectors and core pulls, along with a hydraulic carriage cylinder. Meanwhile, the Spark AE IMMs are all-electric, with hydraulic core pulls offered as an option. The machines are appropriate for molding ultra-thin, ultra-light parts for a variety of markets, including the toy, medical, automotive and electronics sectors.

What’s new? Availability of the IMMs upgraded to meet the needs and requirements of the North American and European markets.

Benefits Precise, efficient, high-speed molding.

CH America, Torrington, Conn., 860-840-7070, www.ch-america.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.