NPE Booth W943

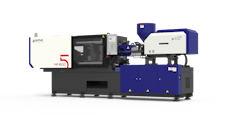

Injection molding machines (IMMs) Absolute Haitian has updated four IMM series: the servo-hydraulic lines, the Mars, with clamping forces from 67 tons to 3,709 tons, and two-platen Jupiter, ranging from 505 tons to 7,418 tons; the all-electric line, the Venus, ranging from 45 tons to 899 tons; and the electric series, Zeres, ranging from 45 tons to 1,551 tons.

What’s new? Generation 5 updates, which includes enhancements in energy efficiency, overall performance and machine intelligence. An electric screw drive now is standard on the servo-hydraulic series up to 120mm. Among other work cells, Absolute plans to display one of its newest Jupiters — a two-platen, 731-ton press equipped with a two-cavity mold at NPE. The machine, called a JU7500V/3450 “A,” will be making an outer panel for vehicles out of a PC and ABS blend in 60-second cycles, with a Haitian Hilectro robot performing part takeout.

Benefits Up to 20 percent in energy savings, decreased machine footprint and faster cycle times. In addition to the other Generation 5 upgrades, the new machines boast control systems that use artificial intelligence and sensors that make possible improvements across an array of characteristics, including energy management, accuracy, consistency, diagnostics and assistance. They offer real-time monitoring and improved integration of auxiliary and peripheral equipment, along with machine monitoring systems. The new electric screw drives for the servo-hydraulic machines improve processing stability.

Absolute Haitian, Worcester, Mass., 508-459-5372, www.absolutehaitian.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.