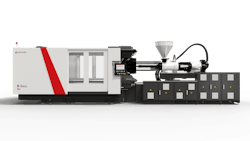

M-Series Milacron’s new M-Series of two-platen injection molding machines is driven by a servo motor hydraulic system and offers clamping forces ranging from 506 tons to 1,236 tons, making it useful for applications from automotive and construction to housewares and furniture. The M-Series features a mechanically synchronized nut lock design, industry-leading tie-bar spacing and improved mold and eject access. All M-Series presses come with a 21.5-inch multi-touch screen with configurable screen layout, and are compatible with Milacron’s M-powered suite of connectivity products. The M-Series can be used with a wide selection of injection unit sizes, barrels and screws, boosting processing flexibility for customers.

What’s new? The M-Series, which was displayed at Fakuma.

Benefits Higher maximum mold weights, faster clamp speeds and a compact clamp footprint. M-Series presses have mold weight carrying capacities ranging from 15,400 pounds to 51,800 pounds. The presses’ Fanuc servo motor hydraulic system offers rugged reliability and improves energy efficiency. The presses also are environmentally friendly, with a smaller footprint, a reduced dry cycle time and decreased need for lubrication.

Milacron LLC, Batavia, Ohio, 513-536-2000, www.milacron.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.