Engel scores patent for improved injection unit

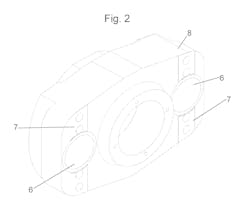

Injection unit. An injection unit for an injection molding machine that reduces the stresses on the machine’s linear drives is the subject of a patent awarded to Engel Austria GmbH, Schwertberg.

Typically, injection molding machines have an injection element that can be in the form of a plasticizing screw and/or an injection piston. Linear drives produce a force that is passed along to the injection element by way of a bearing element, causing the bearing element to deform, according to the patent. A disadvantage “is that upon deformation of the bearing element that deformation directly affects the linear drives. In the case of plate-shaped bearing elements the effect of the force generally results in flexural warping of the plate. The deformation of the bearing element has a further effect in the form of a bending moment on the linear drives, in which case the loading conditions on the linear drives also change,” the patent states.

The injection unit consists of an injection element for introducing a plasticized material into a mold via a linear movement. The injection element is coupled to a bearing element and at least two linear drives; the drives exert a force on the injection element via a transmission element acting on the bearing element. The injection unit has at least one rotational drive configured to cause rotational movement of the plasticizing screw. The two drive motors, preferably spindle drives, are arranged on a fixing plate.

The invention features clearance between the bearing element and the transmission element so that deformations of the bearing element are not transmitted to the transmission element or are transmitted to a reduced degree.

In addition to eliminating or reducing the stresses on the linear drives, the invention prevents the bearing and transmission elements from wedging into each other and also allows for the use of linear drives that are structurally smaller because they don’t have to withstand high stress levels.

In some embodiments of the invention, a measuring diaphragm between one of the linear drives and the transmission element can be used to measure exerted pressure or tensile forces between the two components.

Patent 11,141,894; issued Oct. 12