le for use with injection molding and blow molding machines. The air-cooled units have a cooling capacity of up to 60 tons. With maximum power ranging from 0.75 horsepower (hp) to 7.5 hp, the water-cooled varieties can move up to 160 gallons per minute.

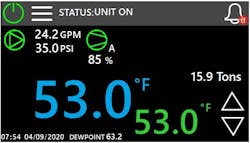

What’s new? The addition of an RJ45 port on all new HMIs. The port provides a connection to a cable or wireless access point that makes possible virtual network computing (VNC). The new HMIs work with air-cooled chillers with capacities ranging from 1 ton to 60 tons and with water-cooled units ranging from 2 tons to 60 tons. They also are available for use with existing chillers.

Benefits Greater flexibility. The VNC allows production managers and other personnel to connect remotely with every HMI and control element in Delta T’s line of variable-speed chillers, and it helps to increase productivity and facilitate around-the-clock production. Users can employ almost any kind of computer device, including tablets, laptops and smartphones, to control their chillers remotely from the local area network (LAN), or via a virtual private network if they are outside the range of the LAN.

Delta T Systems Inc., Richfield, Wis., 262-628-0331, www.deltatsys.com