NPE Booth W6751

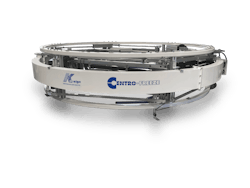

Centro-Freeze Kdesign’s secondary cooling unit for blown film is installed immediately before the lay flat. Kdesign is part of the Reifenhäuser Group and offers technologies in cooling, measurement and calibration.

What’s new? The technology, which is suitable for all new blown film lines as well as for retrofitting in existing lines. It was introduced in the U.S. market last year. Reifenhäuser will be exhibiting Kdesign’s products for blown film at NPE for the first time.

Benefits Increased output and reduced need for anti-block additives. In hot climates and during summer months, blown film manufacturers face a challenge because a film bubble cools more slowly in heat and tends to stick together after being laid flat. To address this, the Centro-Freeze’s air blow-out elements cool the film tube evenly around the entire circumference and thus decrease the film temperature by up to about 29 degrees Fahrenheit, reliably preventing film blocking.

Reifenhäuser Inc., Maize, Kan., 316-260-2122, www.reifenhauser.com

Bruce Geiselman | Senior Staff Reporter

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.