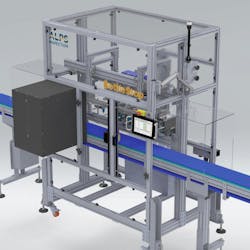

BottleStop This ALPS multi-head leak tester is designed to meet the needs of blow molding manufacturers of large, stable containers. It is appropriate for testing extrusion blow molded HDPE containers, such as household toilet-bowl-cleaner bottles, industrial chemical containers and automotive fuel-additive containers. Boasting advanced control systems, the tester can switch between testing angled and standard necks; an optional probe for choked necks also is available. Features include a full-color touch screen, which provides reports, and a self-test function to verify calibration and ensure reliable detection of even very small defects.

What’s new? The leak tester, which hit the market this winter.

Benefits Ease of use, and automatic, reliable, precise quality control and efficient process monitoring. Applicable with a variety of container types and configurations, the tester is cost-effective and flexible. Blow molders can integrate the BottleStop, which is positioned above the conveyor, seamlessly into their existing production lines with minimal modifications.

ALPS - Air Logic Power Systems LLC, Harrison, Ohio, 800-325-8717, www.alpsleak.com

Vital Statistics

|

Throughput |

Up to 65 containers per minute |

|

Possible configurations |

Use with two, three or four heads |

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.