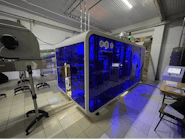

MiPET 4-P This fully electric stretch blow molding machine from Meccanoplastica Srl, Florence, Italy, has four cavities that can transform preforms into PET bottles up to 2 liters in size. It guarantees low energy consumption and an optimized heating system. It has a pressure checking system that allows it to discard defective bottles. Plastics Machinery Group represents Meccanoplastica in North America.

What’s new? A more compact footprint than the machine’s original design, which debuted in 2015.

Benefits Energy savings. This upgraded model introduces ceramic heating elements to optimize the heating of preforms while cutting energy consumption by about 20 percent. The ceramic elements also improve heating performance and speed production time, while they take up much less space than the heat lamp system they replaced, allowing the machine’s overall size to decrease. The machine also offers fast and easy changes of molds and preforms.

Plastics Machinery Group, Bedford Heights, Ohio, 440-498-4000, www.plasticsmg.com

David Tillett | Associate Editor

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.