NPE Booth S11058

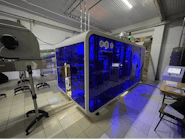

APF-Max 3U This PET Technologies stretch blow molding machine can be used to produce bottles with capacities from 0.1 liter to 8 liters. Such bottles can be asymmetrical, returnable or refillable; made from color or glass-like PET or 100 percent recycled PET; or designed for hot-fill processes. The machine also can make cylindrical bottles at high speeds.

What’s new? The blow molding machine, making its debut at NPE. The APF-Max 3U is the first of PET Technologies’ machines that’s compatible with rotary blow molds — a significant advantage for converters.

Benefits Flexibility, energy efficiency and speed. The fully electric APF-Max 3U is equipped with a near-infrared (NIR) heating system, so it heats up more quickly than machines with conventional infrared systems. This allows it to operate with a relatively smaller heater, reducing its footprint and energy needs. In addition to the energy savings generated by the NIR system, the APF-Max 3U's two-step air-recovery system also provides efficiency. The system recovers air after the main blowing action and sends it to the control system. The machine can use the air for the pre-blowing of the next bottle or for control in the filling line.

PET Technologies GmbH, Neunkirchen, Austria, 347-897-9300, www.pet-eu.com

Vital Statistics

|

Machine dimensions |

20.2 feet by 10 feet by 9.6 feet |

|

Weight |

13,669 pounds |

|

Blowing pressure |

Up to 580 pounds per square inch |

|

Number of possible cavities |

1, 2 or 3 |

|

Possible preform neck diameters |

18mm– 48mm |

|

Maximum throughput |

5,400 bottles per hour |

|

Products that can be contained in bottles produced by the machine |

Water, carbonated beverages, beer, milk and dairy products, household and automotive products |

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.