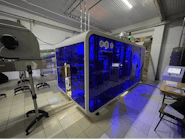

Warp Gauge This Inoex device can be integrated directly into an extrusion blow molding line to measure the wall thickness of parts such as drums or liners for hydrogen vessels and intermediate bulk containers. The gauge generates a grid of measuring points using a sensor that is guided vertically to the part surface. If desired, it also can measure the melt hose within a continuous blow molding line.

What’s new? The device, which Inoex introduced at Interpack in Düsseldorf, Germany, in May.

Benefits Contactless, non-destructive wall thickness measurements when used as a stand-alone device. When used in combination with simple kinematics, it can measure a blow molded part fully automatically after demolding.

Inoex LLC, Lancaster, Pa., 717-672-0870, www.inoex.de

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.