Patent Report: Silgan invents system for forming squeezable containers

Squeezable container. A blow molding system and method for forming a squeezable plastic container from an injection molded preform earned a patent for Silgan Plastics LLC, Chesterfield, Mo.

A squeezable tube container typically is manufactured from an extruded plastic tube that has a separate, threaded head component with an opening for dispensing the contents of the tube. The head component may be attached via welding or an adhesive. Following attachment of the head component, the tube is filled from the other end, which is then sealed via crimping.

Such tubes have a circular cross section at the end that is attached to the head component and the opposite end is flat, meaning that the circumference varies along the length of the tube. “Further, making tubes using the extrusion-based process may generate significant waste or scrap material due to the starting and stopping of the extrusion machinery or other machinery at various stages of the process,” the patent states. “In addition, the extrusion-based process involves an additional step to attach the separate head component to the tubular container body.”

The invention has advantages over the extrusion process, such as the ability to make the container from a transparent resin, or from an orientable polymer, such as PP. When using an orientable polymer, the multi-step stretch blow molding process aligns its molecules so that the material of the finished container is biaxially oriented, improving its strength while still allowing it to be squeezed. The system and process also can produce containers faster than the extrusion method and reduce production waste.

The method generally includes making a preform via injection molding and forming a tubular container from the preform via blow molding. In various embodiments, the closed end of either the preform or the blow molded container is cut or trimmed to create a dispensing opening and the open end of the container is cut or trimmed to create a smooth opening that is used to fill the container. Such containers are suitable for holding and dispensing liquids, gels and pastes, such as cosmetics, foods and cleaning products.

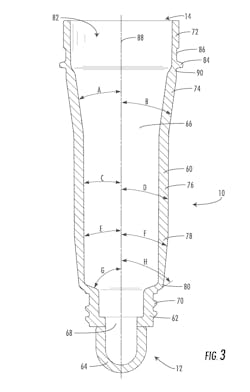

The system includes a mold body and a base portion; the mold body has a central bore that runs from one end to the other along a longitudinal axis. The base portion includes a recess that, when positioned at the end of the mold body, forms a blow mold cavity in conjunction with the central bore. The system has at least two interchangeable base portions that allow for containers of different sizes, or with different neck sizes, to be formed.

Patent 11,065,802; issued July 20