Pakman Proco Machinery regularly updates its Pakman robotic packaging systems for blow molded containers. The portable systems allow for quick tooling changeovers, making them easily adaptable to different containers and packing patterns.

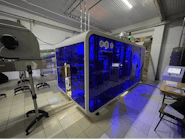

What’s new? The latest generation, which features a Yaskawa Motoman HC10 or HC20 collaborative robot; previous Pakman systems incorporated a six-axis articulated robot. The cobot, an infeed conveyor and a box feeder are all mounted onto a common frame outfitted with leveling pads and casters. A collating, indexing accumulation system stages each layer of bottles so it can be picked up by Proco’s end-of-arm tooling and placed inside a box. A new option is the ability to pack layers of bottles neck down.

Benefits Efficiency. The compact systems reduce handling of the bottles and are less expensive than conventional automation. They easily fit between blow molding lines and can be quickly moved into position, set up and put into production. Additionally, the cobots need minimal training for new tasks.

Proco Machinery Inc., Mississauga, Ontario, 905-602-6066, www.procomachinery.com