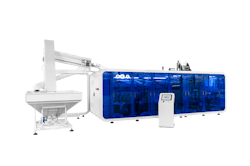

PET Technologies recently brought to the market a new generation of APF-Max blow molding machines, which can manufacture PET bottles in a wider range of sizes of than their predecessors.

The new machines are more flexible and also allow for the production of wide-neck jars, the company said.

“The whole APF-Max series is a new design,” Tetiana Pronikova, PET Technologies’ head of regional development for the Americas, said. “The first machines — four, six and eight cavities for up to 3-liter bottles — were released in 2018. At the end of 2020, the APF-Max series was extended with two-, three- and five-cavity models. Now, the maximum bottle volume that can be produced is 6 liters. With the same machine, the customer can produce both 1-liter and 6-liter bottles. It is just necessary to change the mold and make some adjustments in the machine.”

The smallest bottles the machines can make are 100 milliliters. Output varies between 3,000 and 14,000 bottles per hour.

The machines also are more versatile. For example, an APF-Max four-cavity machine can make bottles as small as 100 milliliters, but it can be converted to a two-cavity machine capable of manufacturing 6-liter bottles.

The machines can produce bottles with a wide range of neck sizes. For example, a single machine can produce 100-milliliter bottles with narrow necks for hand sanitizer and 1-liter wide-neck jars for coffee, the company said. The new APF-Max 5, for example, can make bottles as large as 2 liters in five cavities. If a company wants to increase the size of the bottles to 5 liters, it can do so by reconfiguring the machine to three cavities.

In addition, the machines have an option for producing bottles for hot-fill applications.

The machines are now in production. At press time, PET Technologies had not yet released specific product literature in print or on its website, but anticipated releasing that information soon.

The machines are streamlined and modular, which allows them to be transported in two parts for easy shipping, and then assembled at the customer’s site, the company said.

The electric cabinet is located on the back of the machine and all communications are connected through the top of the machine – space-saving measures that allow the machine to be placed closer to a wall than is possible with traditional configurations. The APF-Max is equipped with a B&R PLC. The PLC program and manuals for the machine are available in multiple languages.

A central lubrication system simplifies maintenance.

The machines have non-spill connectors designed for quick mold changes and are replaced in one piece. A mold change typically takes only 15 minutes, the company said.

The all-electric APF-Max features high-speed servo drives that provide precise positioning. The stretching rod position is automatically controlled depending on the bottle height when the operator switches from one bottle format to another.

APF-Max machines are equipped with an energy-efficient, near-infrared (NIR) heating system that ensures uniform temperature distribution between the inner and outer parts of a preform wall. NIR heating systems reduce heating times and energy consumption while also requiring less space. Ceramic reflectors are used for better preform heating and to reduce energy consumption.

Bruce Geiselman, senior staff reporter

Contact information:

PET Technologies GmbH, Neunkirchen, Austria, 347-897-9300, https://pet-eu.com/

Bruce Geiselman | Senior Staff Reporter

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.