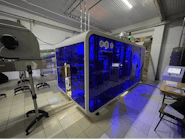

Athena Automation has added a new option to its growing product line, having recently shipped a 387-ton press configured for stack molding, and is rebranding all its injection molding machines as Niigon models. The new stack machine features:

• Dual, inline opposed injection units;

• A wide, stable carrier-bearing stance;

• A remote control for the second injection unit;

• And optional robots.

Robert Schad founded Athena Automation in Vaughan, Ontario, in 2008. He said that when using a stack configuration, the injection press provides higher output on the same floor space using existing molds, and features easy mold access and maintenance. It allows for the installation of two standard molds that can make two different parts of different colors or resins at the same time. The molds are installed with no sprue bar and with conventional hot runners.

"In some cases, we can get twice the output on the same floor space," Schad said.

Athena now offers basic Niigon machines in six tonnages from 166 tons to 608 tons of clamping force. The basic machines can be ordered with a long list of pre-engineered options, including stack molding.

According to Schad, several Niigon machines configured for cube molding have been running at customers' plants for about one year. The first stack machine was delivered about four months ago. A PET version can run two standard 96-cavity preform molds.

During a recent interview at Athena's two-year-old manufacturing plant, Schad said the Niigon 350 has the industry's most rigid base, accurate platens and has best-in-class mold capacity by size and weight. It has dedicated support rails for the stack molds.

The Niigon 350 name refers to its 350 metric tons of clamping force.

Schad also said the Niigon 350 is at least as energy-efficient as comparable all-electric injection presses. Athena machines use an on-demand servo pump to manage hydraulic functions and servo ball screws to control clamping movements. Mold water and hydraulic oil lines are routed to both sides of the center section.

All services connect to the injection end and there is clearance under the machine for cleaning and finished parts conveying. The mold is accessible from both sides, as well as the top of the press.

Tie-bar clearance is 32.5 inches by 32.5 inches and daylight is up to 98.5 inches.

Athena Automation has increased the factory warranty on its injection molding machines from three to five years. Customers can also buy spare parts directly from suppliers. Technical and commercial support now is provided by dedicated regional managers.

Athena builds and tests its presses as they are ordered. Most are ready to be shipped in about eight weeks. The company has 85 employees.

The Niigon brand first appeared on an Athena injection molding machine in 2017, but Schad has a long association with the Ojibwa word, which means "for the future."

Schad worked with a First Nation reserve near Georgian Bay, Ontario, to launch Niigon Technologies Ltd., a custom molding business, in 2001. Today the business continues to operate under a different name and ownership.

Schad said all of Athena's injection molding machines will now carry the Niigon brand.

Ron Shinn, editor

Contact:

Athena Automation Ltd.Vaughan, Ontario, 905-265-0277,

Ron Shinn | Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.