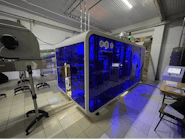

System Cooling AST Technology's platform is designed to monitor flow and temperature circuits within an injection mold. Users can monitor data via a remote, mounted touch screen controller that will monitor and display the flow and temperature for every circuit.

What's new? Its official release at NPE. It is a comprehensive system for tracking water flow and temperature throughout the entire mold.

Benefits Because cooling makes up 60 percent of a mold's overall cycle time, this platform can be used to help reduce or control cycle times and stabilize part quality. With the touch-screen controller, users can set warning and alarm limits for flow and temperature to all zones individually; view current status graphically or as text; feed alarm signals to an ancillary device (alarm tower, hot runner controller or molding machine); and store data and mold setups in the internal memory where they are time- and date-stamped for traceability.

AST Technology North America Inc., Wauconda, Ill., 847-487-1000, www.asttech.com