By Lynne Sherwin

I came. I saw. I walked ... a lot.

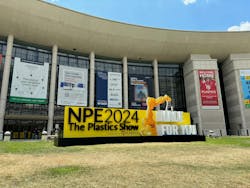

I wouldn’t say I conquered, but at least I survived my first NPE.

When the pandemic hit, some wondered whether the era of big trade shows was over. Who would want to be in a room with that many people? Shaking hands? Eww.

But the Plastics Industry Association (PLASTICS) immediately began touting NPE2024 after a surge in COVID cases forced the cancellation of the 2021 edition. The plastics community responded: Over a million square feet of floor space was sold to accommodate more than 2,000 exhibitors for the return of the show.

PLASTICS reported more than 50,000 registrants, somewhat below the projected 55,000. Almost two-thirds of them were first-timers, and 30 percent were under the age of 40.

Karen Hanna, Bruce Geiselman and I spoke with more than 150 equipment manufacturers, other exhibitors and attendees. Most seemed pleased with the event, but the praise wasn’t unanimous.

People at various booths, and even in the airport lines after the show closed, remarked on the smaller size of the crowd compared with 2018, when PLASTICS put the registration figure at a little over 56,000.

While one man said the experience might make him think twice about returning, Jim Boos, manager of sales and marketing for Wilmington Machinery, was taking things in stride. "Maybe attendance is down," he said, "but it seems like the right people are here." The Wilmington, N.C., company makes injection molding and rotary blow molding machinery and systems, and Boos said business has been strong.

Some machinery makers reported they were writing a lot of quotes, but that they didn’t expect purse strings to loosen until the November election is over and the economic picture clarifies. Others said their customers are still trying to fill the capacity of equipment originally purchased for pandemic needs.

A reduction in aisle traffic wasn't the only change from six years ago. Steven Ross, senior manager of strategic sales and marketing for Sumitomo (SHI) Demag, noted that companies' marketing strategies seem to have evolved, with fewer giveaways and fewer brochures. Just like the machines, marketing is going high-tech:

"Six years ago, we had a lot of paper, we had brochures. And it was everywhere. Now it's a little bit of a cleaner look. And people really liked that digital approach."

Ross said his company had sold machines off the floor — a triumph other companies celebrated with signs proclaiming their machines' future homes. One injection molding machine maker posted special NPE-only deals at its booth.

Beyond the shiny machines on display, our conversations with exhibitors and attendees often centered on the big questions facing the industry: How can equipment manufacturers help processors overcome labor shortages and the skills gap? What’s the role of smart technology and automation, and how can they be made easier to adopt? How can the industry become more sustainable and energy-efficient, and fight negative public perceptions?

Over the next few months, PMM will be reporting on innovations from the show, and how they might help answer those questions. It’s not too late to have yours considered for inclusion. Email detailed information and a high-res photo to [email protected].

NPE wasn’t all serious business:

The swag: After hearing tales of lawn chairs and lady statues, I expected more giveaways. Arburg’s teal toolbox generated long lines, and one guy ahead of me at the FedEx center was shipping out three crates of Milacron’s buckets made in part from recyclate.

One small team of exhibitors split time between their booth and hunting expeditions in both West and South Halls looking to fulfill a real-life Pokémon mission: For them, when it comes to trade show handouts, they told Plastics Machinery & Manufacturing, you gotta catch 'em all.

However, most of the items coming off the lines joined the endless parade of bright green tubs rolling to the onsite recycling centers.

Grooviest booth: Integrated Control Technologies’ ’70s-themed stand, complete with psychedelic bubble lettering, rainbow colors, peace signs, flower decals and disco-ball reception desk. It was a cheerful deviation from the sleek postmodern designs most companies favored.

Most coveted desk toy: A miniature 3D-printed working extruder at the HCS booth, demonstrating a monitoring technology from SpecView. (Too bad it wasn’t a giveaway!)

Neat trick: Yushin’s FRA robot playing with a Kendama toy and doing a little victory dance every time it caught the ball. The robot, unlike us humans putting thousands of steps a day on our pedometers, didn’t get tired or sore.

About the Author

Lynne Sherwin

Managing Editor

Managing editor Lynne Sherwin handles day-to-day operations and coordinates production of Plastics Machinery & Manufacturing’s print magazine, website and social media presence, as well as Plastics Recycling and The Journal of Blow Molding. She also writes features, including the annual machinery buying survey. She has more than 30 years of experience in daily and magazine journalism.